Precision Leveler

Corrective leveling machine for straightening metal sheets and parts

Corrective leveling machine for straightening metal sheets and parts

- Roll diameter: 30-60mm

- Leveling thickness: 3-10mm

- Leveling width: 50-1000mm

A precision leveler is a machine used in metalworking to flatten or straighten metal sheets or coils with high precision. It works by passing the material through a series of rollers or leveling heads that apply pressure to specific areas, adjusting the curvature of the metal to achieve a flat or uniform surface. The process continues until the desired level of flatness or straightness is achieved.

Automotive high-strength steel sheet

Laminated steel sheets for medical use

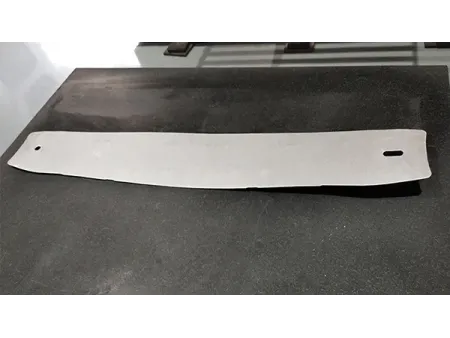

Break pad

Punch sets

- Features

- Specifications

- Components

- Dual Roller Drive: Features a servo motor coupled with a high-precision gearbox, ensuring smooth and stable operation of the leveling rollers.

- CNC Closed-Loop Control

Utilizes a full CNC system with real-time feedback via displacement sensors to maintain constant gap accuracy between rollers. - Enhanced Gear System

The gears are optimally designed for even distribution of power to the rollers, featuring fine grinding and heat treatment for reduced noise and increased durability. - Robust Roller Construction

Includes 23 high-strength alloy steel rollers, each hardened to enhance mechanical properties and extend operational life. - Advanced Roller Pitch Technology

Employs an unequal roller pitch arrangement to optimize stress relief during the leveling process. - Individual Roller Drive

Each roller is driven independently by a cardan shaft, providing precise control and enhanced performance. - Superior Bearing System

Rollers are supported by needle bearings, sealed to prevent contamination and designed for extended maintenance intervals.

Designed for high-precision flattening, this leveler excels with a range of materials including aluminum, stainless steel, carbon steel, and copper plates. It is especially effective in applications requiring precise flatness such as automotive parts, aerospace structures, high-speed rail components, and metal furniture and electrical enclosures.

Precision Leveling Machine (30mm Roll Diameter)

| Model | ||||

| Roll diameter | Ø30mm | Ø30mm | Ø30mm | Ø30mm |

| Quantity of rolls | 21 | 21 | 21 | 21 |

| Rated leveling width | 300mm | 500mm | 800mm | 1000mm |

| Rated plate thickness | 0.5-2mm | 0.5-2mm | 0.5-2mm | 0.5-2mm |

| Max. plate thickness | 3mm | 3mm | 3mm | 3mm |

| Leveling accuracy | H | H | H | H |

Precision Leveling Machine (40mm Roll Diameter)

| Model | ||||

| Roll diameter | Ø40mm | Ø40mm | Ø40mm | Ø40mm |

| Quantity of rolls | 21 | 21 | 21 | 21 |

| Rated leveling width | 300mm | 500mm | 800mm | 1000mm |

| Rated plate thickness | 0.5-3mm | 0.5-3mm | 0.5-3mm | 0.5-3mm |

| Max. plate thickness | 5mm | 5mm | 5mm | 5mm |

| Leveling accuracy | H | H | H | H |

Precision Leveling Machine (50mm Roll Diameter)

| Model | ||||

| Roll diameter | Ø50mm | Ø50mm | Ø50mm | Ø50mm |

| Quantity of rolls | 21 | 21 | 21 | 21 |

| Rated leveling width | 300mm | 500mm | 800mm | 1000mm |

| Rated plate thickness | 0.5-4mm | 0.5-4mm | 0.5-4mm | 0.5-4mm |

| Max. plate thickness | 8mm | 8mm | 8mm | 8mm |

| Leveling accuracy | H | H | H | H |

Precision Leveling Machine (60mm Roll Diameter)

| Model | ||||

| Roll diameter | Ø60mm | Ø60mm | Ø60mm | Ø60mm |

| Quantity of rolls | 21 | 21 | 21 | 21 |

| Rated leveling width | 300mm | 500mm | 800mm | 1000mm |

| Rated plate thickness | 1-6mm | 1-6mm | 1-6mm | 1-6mm |

| Max. plate thickness | 10mm | 10mm | 10mm | 10mm |

| Leveling accuracy | H | H | H | H |

Configurations

- CNC controller: Delta (Taiwan)

- Servo motor: Mitsubishi (Japan)

- Servo drive: Mitsubishi (Japan)

- Inverter: Mitsubishi (Japan)

- Angle displacement sensor: Miran (China)

- Low-voltage electrical components: Schneider (France)

Why precision levelers are needed in the sheet-metalworking industry

Automotive high-strength steel sheet

Laminated steel sheets for medical use

Break pad

Punch sets

- Shape Correction

Precision levelers address deformations in sheet metal caused by manufacturing, transportation, or usage, restoring them to their original design specifications. - Ensuring Compliance with Precision Standards

In sectors like automotive and aerospace, where stringent flatness standards are critical, precision levelers ensure that metal workpieces meet these exacting requirements. - Process Integration

These machines facilitate the adjustment of metal workpieces to specific shapes required for further processing, enhancing overall manufacturing quality and consistency. - Deformation Rectification

Precision levelers repair deformations resulting from welding, heating, or other industrial processes, ensuring the workpiece complies with technical standards. - Aesthetic Enhancement

By improving the surface finish, precision levelers enhance the visual and professional appeal of metal products.

Key Components