PSD Top Discharge Centrifuges with Filter Bag

The PSD top discharge centrifuges with filter bag are solid-liquid separation equipment in base plate design. This series of industrial centrifuge is endowed with simply structure, reliable performance, easy operation and maintenance. Filtration time allows for free adjustment, resulting in effective cake washing and undamaged solid phase. Moreover, filter bag can be readily cleaned.

Main Features of PSD Top Discharge Centrifuge

1. This wastewater treatment equipment employs variable frequency drive to achieve stable start-up and adjustable centrifugal force.

2. Thanks to filter bag discharge method, our sludge treatment machine brings minimized damage to solid phase, and offers reduced workload, enhanced efficiency and exceptional versatility.

3. Well-conceived structure design features smooth and polished surface for complete residual heel removal. With the design of hinged cover, it’s much easier to clean the gap between housing and basket.

4. Machine base and basket are welded together in a holistic approach to offer impressive load bearing capacity.

5. Platform base design comes with low center of gravity and minimized footprints. Moreover, the base can be regarded as operation platform for convenience.

6. Four-point liquid damping vibration absorber is introduced for excellent performance and simplified maintenance.

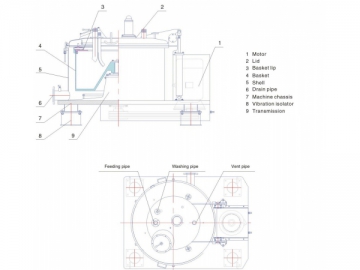

7. There are general pipes and viewing window placed on the hinge cover, including feeding pipe, washing pipe, inspection window and lighting hole, etc.

8. Optional CIP system is available to wash interior parts such as inner wall of top discharge centrifuge housing, liquid slot and inner and outer side of basket, etc. Enhanced sanitation status is provided to meet GMP standards.

9. Enclosed structure is guaranteed by utilization of silicone rubber or fluororubber. Optional nitrogen protection system enables our top discharge centrifuge to be applicable for poisonous, flammable and explosive environments.

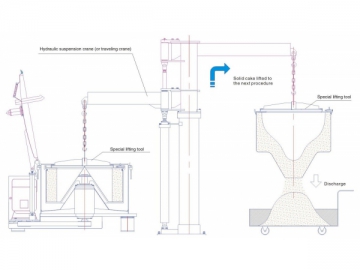

10. Optional hydraulic crane with stainless steel housing is also presented for your needs of easy discharge and high sanitation level.

Main Application of PSD Top Discharge Centrifuge

This industrial separation machine is highly suitable for solid-liquid separation of slurries containing granules and fibrous materials, such as plaster, copper sulfate, potassium chloride, borax, dyestuff, pesticide, salt, gourmet powder, food additive, starch, sugar, chemical seasoning, antibiotic, vitamin, as well as sludge treatment, wastewater treatment and metal refining like including copper, zinc and aluminum, etc.

Schematic Diagram of PSD Top Discharge Centrifuge

Technical Parameter of PSD Top Discharge Centrifuge

| Item | Model | ||||||

| Basket Dia.(mm) | 800 | 1000 | 1200 | 15250 | 1500 | 1600 | 1800 |

| Basket Volume (L) | 100 | 175 | 350 | 400 | 600 | 730 | 910 |

| Max. Load (kg) | 135 | 250 | 470 | 530 | 800 | 880 | 1100 |

| Max. Speed (rpm) | 1200/1500 | 1000/1200 | 960/1050 | 960/1050 | 850 | 800 | 780 |

| Centrifugal Force | 645/1006 | 560/806 | 620/740 | 645/770 | 645 | 647 | 612 |

| Motor Power (kW) | 5.5/7.5 | 11/15.0 | 15/18.5 | 18.5/22 | 30 | 37 | 37 |

| Dimension (L×W×H) (mm) | 1500×1200 ×1230 | 1790×1380 ×1290 | 2140×1620 ×1520 | 2140×1620 ×1520 | 2600×2200 ×1800 | 3050×2300 ×1730 | 3300×2600 ×2100 |

| Weight (kg) | 2300 | 3500 | 3000 | 3000 | 5000 | 7500 | 10000 |