KM211 Hydraulic-controlled Bolting Rig

The KM211 hydraulic rock bolting rig is specially designed for the construction of rock bolts in the pipe seam of low tunnels and it is capable of passing through tunnels 2.5 meters wide and 1.7 meters high. It is qualified for anchoring operations in tunnels whose section extends to a width of over 2.5 meters and a height of over 2.8 meters.

Application and Features

1. Complete functions

The advancing beam at two stations is available and it is equipped with a magazine with a storage capacity of 10 bolting rods, along with an optional protective netting module. It is capable of performing the following tasks: drilling, netting and installation of rock bolting rods.

2. High safety

Operators are protected by the ceiling, far away from the danger area.

3. High efficiency

The stepped piston is used for the high-frequency rock drill and this can improve the transmission efficiency of impact wave, increasing drilling speed and reducing the consumption of drilling tools.

4. Good view for the operator

The articulated chassis of four-wheel drive ensures the flexible, quick and safe driving in narrow tunnels.

5. Considerable space

Considerable space and automatic functions enable the driver to concentrate on drilling in a safe, fast and accurate manner.

6. Easy maintenance

All the relevant parts are protected from the outside environment and are easy to maintain.

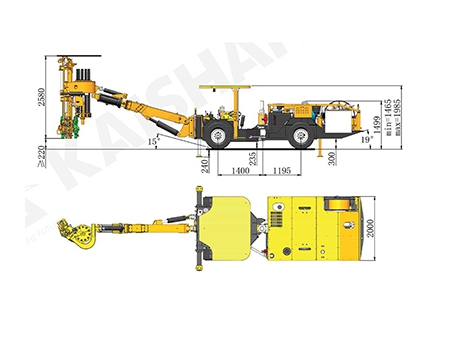

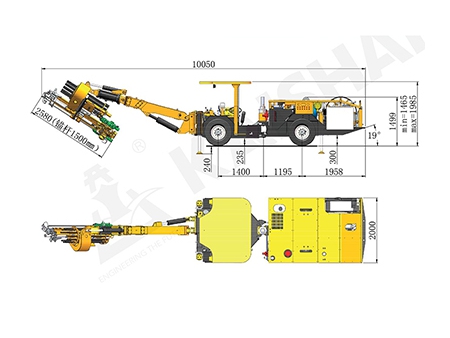

- Dimension

- Transport dimension

- Turning Radius

1. Dimensions and weight

| Length | 10700mm | |

| Width | 2000mm | |

| Height | 1500/2000mm | |

| Weight | Appr.12000kg | |

| Tramming speed on flat ground | 10km/h | |

| Maximum climbing capacity | 25%(14°) | |

| Air compressor | 1×JN5 | Oil consumption of lubrication | 180-250 g/h |

| Capacity of air compressor | 0.5m³/min | ||

| Pressure | 6-8 bar | Water pump | 1×CR3 |

| Device of shank lubrication | Electronic pulse lubrication pump | Power | 1.5kW |

| Air consumption of lubrication | 0.3m³/min | Capacity of water pump | 3m³/h |

| Noise level | <100dB(A) | |

| Lifting safety roof | Meet the requirements of FOPS and ROPS | |

| Diesel engine | Cummins QSB3.9 -C80-31/60kW/2200rpm | Travelling braking | Hydrostatic brake |

| Exhaust purification | Exhaust catalyst | Parking braking | Web multidisc brake |

| Drive system | Closed travelling system of four-wheel drive | Fuel tank | 60L |

| Dilling | Bolt Rod Install | |

| Rock drill | 1×HC25/R32 | 1×HC25/R32 |

| Impact power | 8KW | 8KW |

| Impact flow | 65L/min | 65L/min |

| Impact pressure | 150bar | 150bar |

| Maximum rotary pressure | 175bar | ------ |

| Impact Frequency | 55-65Hz | 55-65Hz |

| Torque | 325Nm | ------ |

| Hole diameter | 32-51mm | |

| Beam rotation | 360° | |

| Feed extension | 480mm | |

| Applicable height of tunnel | Bolt rod length 1500mm | |

| Motor | 45kW | ||

| Impact/Feed/Positioning | Axial variable displacement piston pump | ||

| Rotation | Gear pump | ||

| Filter fineness | 10 μ | ||

| Hydraulic oil tank | 240L | ||

| Hydraulic cooler | Water cooler | ||

| Working voltage | 380V | ||

| Frequency | 50Hz | ||

| Starting method | Star-triangle | ||

| Cable reel | 1×K440 | ||

| length of reel cabling | 100m | ||

| Outer diameter of cable | φ28mm | ||

| Cable specifications | 3×25 3G6 |