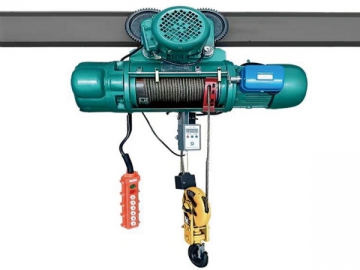

Electric Hoist

Request a Quote

Product Information:

The electric hoist is a specially designed piece of lifting equipment. Generally, it is installed in single-girder cranes, bridge cranes, gantry cranes, jib cranes. Electric hoists have small volume and light dead loads, so it is simple to operate and use. It is suitable for industrial and mining enterprises, warehousing, docks and other places. After slight modification, it can also be used as a hoist. Therefore, it is an indispensable machine for improving productivity and improving working conditions.

| Type | CD1,MD1 | |||||||||||||||||||||||||||||||||||||||

| Lifting Capacity | T | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | 20 | |||||||||||||||||||||||||||||||

| Lifting Height | M | 3 | 6 | 9 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 9 | 12 | 18 | 24 | 30 | 9 | 12 | 18 | 9 | 12 | 18 | |

| Lifting Speed | m/min | 8 0.8/8 | 8 0.8/8 | 8 0.8/8 | 8 0.8/8 | 8 0.8/8 | 7 0.7/7 | 3.5 0.35/3.5 | 5 | |||||||||||||||||||||||||||||||

| Operating Speed | m/min | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20 | 20 | |||||||||||||||||||||||||||||||

| Steel Wire | Diameter | mm | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | 22.5 | ||||||||||||||||||||||||||||||

| Structure | 6×37 | 6×37+1 | 6×37+1 | 6×37+1 | 6×37+1 | 6×37+1 | 6×37+1 | 6×37+1 | ||||||||||||||||||||||||||||||||

| Operating Track | 16-28b | 16-28b | 20a-32c | 20a-32c | 25a-63c | 32b-63c | 32b-63c | 56c-63c | ||||||||||||||||||||||||||||||||

| Min Curvature Radius | m | 1.5 | 1.5 | 2 | 2 | 3 | 4 | 2 | 2.5 | 3 | 4 | 2 | 2.5 | 3 | 4 | 2.5 | 3 | 4 | 4.5 | 6 | 3.4 | 4 | 6 | 7.5 | 9 | 3.5 0.35/3.5 | 4 | 6 | ||||||||||||

| LifingMotor | Type | ZD₁ 21-4 | ZD₁ 22-4 | ZD₁ 31-4 | ZD₁ 32-4 | ZD₁41-4 | ZD₁ 51-4 | ZD₁ 51-4 | ZD₁52-4 | |||||||||||||||||||||||||||||||

| ZDS 0.2/0.8 | ZDS 0.2/1.5 | ZDS 0.4/3 | ZDS 0.4/4.5 | ZDS 0.8/7.5 | ZDS 1.5/13 | ZDS 1.5/13 | ||||||||||||||||||||||||||||||||||

| Power | kw | 0.8 0.2/0.8 | 1.5 0.2/1.5 | 3 0.4/3 | 4.5 0.4/4.5 | 7.5 0.8/7.5 | 13 1.5/13 | 13 1.5/13 | 18.5 | |||||||||||||||||||||||||||||||

| Rotational Speed | r/min | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | 1400 | |||||||||||||||||||||||||||||||

| Electric Current | A | 2.4 0.72/2.4 | 4.3 0.72/4.3 | 7.6 1.25/7.6 | 11 2.4/11 | 18 24/18 | 30 5.2/30 | 30 5.2/30 | ||||||||||||||||||||||||||||||||

| Operating Motor | Type | ZD₁11-4 | ZD₁ 11-4 | ZD₁ 12-4 | ZD₁ 12-4 | ZD₁21-4 | ZD₁ 21-4 | ZD₁ 21-4 | ZD₁21-4 | |||||||||||||||||||||||||||||||

| Power | kw | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8×2 | 0.8×2 | 0.8×2 | |||||||||||||||||||||||||||||||

| Rotational Speed | r/min | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |||||||||||||||||||||||||||||||

| Electric Current | A | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | 4.3 | |||||||||||||||||||||||||||||||

| Combine Numbers | Times | 120 | ||||||||||||||||||||||||||||||||||||||

| Working System | Middle Rank FC=25% | |||||||||||||||||||||||||||||||||||||||

| Power | 3 AC 380V 50Hz | |||||||||||||||||||||||||||||||||||||||

| Basic Size | L | mm | 616 | 688 | 760 | 758 | 856 | 954 | 1150 | 1346 | 1542 | 820 | 920 | 1020 | 1220 | 1420 | 1620 | 932 | 1038 | 1138 | 1327 | 1533 | 1738 | 1047 | 1157 | 1257 | 1467 | 1677 | 1887 | 1602 | 1783 | 2145 | 2507 | 2869 | 1802 | 2089 | 2345 | |||

| L1 | 274 | 346 | 418 | 345 | 443 | 541 | 737 | 933 | 1129 | 352 | 452 | 552 | 752 | 952 | 1152 | 380 | 483 | 586 | 792 | 998 | 1204 | 415 | 525 | 625 | 835 | 1045 | 1255 | 875 | 1056 | 1418 | 1780 | 2142 | 1175 | 1356 | 1718 | |||||

| L2 | 125 | 158 | 187 | 229 | 267 | 301 | 301 | |||||||||||||||||||||||||||||||||

| L3 | 318 | 390 | 462 | 401 | 499 | 597 | 793 | 989 | 1185 | 418 | 518 | 618 | 818 | 1018 | 1218 | 448 | 551 | 654 | 860 | 1060 | 1272 | 485 | 606 | 695 | 905 | 1115 | 1325 | 949 | 1130 | 1492 | 1854 | 2216 | 949 | 1130 | 1492 | |||||

| L4 | 190 | 196 | 240 | 264 | 320 | 376 | 376 | |||||||||||||||||||||||||||||||||

| B | 884 | 884 | 930 | 930 | 1055 | 1055 | 1055 | 1055 | ||||||||||||||||||||||||||||||||

| H | 650 | 667 | 767 | 840 | 950 | 954 | 1058 | 1120 | 1183 | 1350 | 2100 | 2400 | ||||||||||||||||||||||||||||

| D | 16.5 | 19 | 25 | 25 | 31 | 37 | 41 | |||||||||||||||||||||||||||||||||

| Dead Load ±10% | CD11 | kg | 121 | 125 | 130 | 137 | 145 | 172 | 188 | 204 | 220 | 221 | 232 | 285 | 309 | 332 | 353 | 281 | 297 | 354 | 390 | 420 | 451 | 437 | 495 | 597 | 646 | 686 | 726 | 1048 | 1098 | 1209 | 1301 | 1411 | 1130 | 1183 | 1286 | |||

| MD11 | 138 | 142 | 147 | 164 | 174 | 199 | 215 | 231 | 247 | 256 | 267 | 320 | 344 | 361 | 388 | 311 | 327 | 384 | 420 | 450 | 481 | 530 | 532 | 654 | 703 | 743 | 783 | 1104 | 1154 | 1265 | 1366 | 1467 | 1220 | 1373 | 1376 | |||||

| 89 | 92 | 99 | 105 | 112 | 120 | 135 | 159 | 165 | 166 | 176 | 186 | 209 | 229 | 249 | 222 | 236 | 250 | 284 | 312 | 340 | 377 | 400 | 415 | 456 | 493 | 529 | 795 | 841 | 943 | 1035 | 1127 | 1130 | 1183 | 1286 | ||||||

| 106 | 111 | 116 | 132 | 140 | 147 | 162 | 177 | 192 | 201 | 211 | 221 | 244 | 264 | 284 | 252 | 266 | 280 | 314 | 342 | 370 | 430 | 457 | 472 | 513 | 549 | 586 | 851 | 897 | 999 | 1091 | 1183 | 949 | 997 | 1090 | ||||||

- Wire rope electric hoist uses a mechanical and electrical integration design, by the replacement of different molds, you can get different specifications’ wire rope. And it is simple and safe to be controlled, it is convenient to inspect the device and maintain the motor. Its main disadvantages are poor motor thermal conditions, poor grouping, and complex power supply devices, manufacturing, and assembly.

- The components of the wire rope electric hoist are: motor, transmission mechanism, reel and sprocket. By the different relative locations of motor and reel, the electric hoist can be roughly divided into four types. The pressed steel wire rope has large pulling force, beautiful appearance, and can be fast pressed. In just a few minutes we can complete the pressure welding of a steel wire rope, which greatly reduces labor intensity and improves work efficiency.

- The electric hoist whose motor is installed outside the winding drum has the advantages of good grouping, high degree of generalization, and it is easy to change the height of lifting and inspect the device.

- Electric hoist is mainly divided into: electric chain hoist, wire rope electric hoist (explosion-proof hoist), anti-corrosion electric hoist, double winding drum electric hoist, winch, mini electric hoist, group hoist electric hoist and multi-function hoist.

Index

heavy duty crane, container handling crane, industrial crane, shipyard crane

Related products

Send Message

Most Recent

More

Other Products

Videos