Anti-UV Anti-Oxidation Additive Masterbatch

Application

UV resistant anti-oxidation additive masterbatches are commonly used in plastic road signs and other plastic products such as roadblocks, plastic stadium barriers, ball boxes, outdoor plastic chairs, plastic lawns, car sunshade cloths, swimming pools and floating balls that are left outside year round. This additive is designed to slow the aging process and improve the service life of each product it is used in.

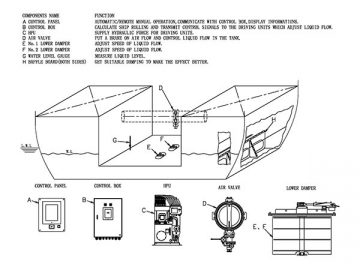

Technical index

1. This masterbatch is suitable for PE, PP, PVC, and EVA with a recommended addition of 2-4%.

2. Appearance: Granular cylinder with a diameter and length of 4mm, respectively

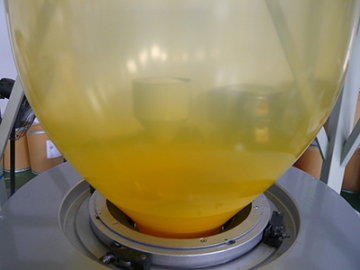

3. Basic material: We use two types of imported anti-oxidants and one imported UV resistant agent and mix them using a banbury mixer that is complementary and features a double resistant effect.

4. Color: It is light yellow and grainy.

Practical significance

This additive consists of two types of important antioxidants and one imported UV resistant agent that are mixed using a Banbury mixer for a complementary and double resistance effect. Using this additive in plastic products used in certain circumstances and feature specific requirements for things like color, appearance and shape improves their aging resistance and increases the service life. Factors that will age a plastic product include temperature and force, though the main causes of oxidation in plastic products is natural, environmental conditions such as UV illumination. These antioxidants will not change color, or pollute the environment. They feature an excellent heat resistance, oxygen resistance, aging resistance, excellent thermal stability and no volatilization, making them useful in polypropylene, polyethylene, polyoxymethylene, ABS resin and various synthetic rubber and petroleum products, protecting them from thermal oxidative degradation. This additive also has an outstanding compatibility, high extraction resistance, low volatility, no odor and no taste.

The UV resistant agent features a highly absorbent UV capacity in ultraviolet spectral range (especially 300 to 400nm), giving it an excellent light stability effect for plastic products. It also has an excellent compatibility with thermoplastic resin, especially polyolefin, thus ensuring the uniformity of dispersion in the polymer. The extremely low evaporation pressure also avoids any product loss during process, while a low migration property avoids spraying frost. An excellent heat resistance also avoids significant degradation and volatilization at extrusion temperatures. It shows a chemical inertness in resins and dressings produced by plastic manufacturers, which ensures the resin will not smell. The agent also features a unique, high purity, so that it will not cause any negative effects due to impurities.

Index

plastic masterbatch, master batch, polymer, plastic additive