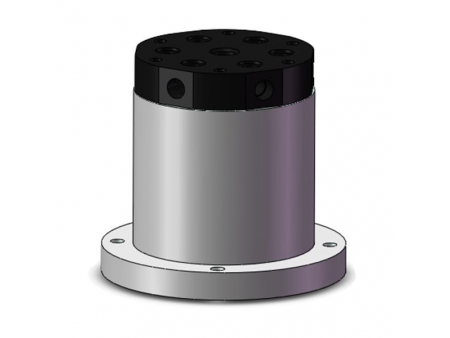

Couplings

Couplings include sucker rod coupling, tapered coupling and polished rod coupling.

The internal threads at both ends of the sucker rod couplings are identical and they are used to connect sucker rods of the same size or sinker bar with sucker rod thread.

The internal threads at both ends of the reducing couplings are different and they are used to connect sucker rods of different sized or to link polished rod and sucker rod.

The internal threads at both ends of the polished rod coupling are identical (cone angle=9°), and they are used to connected polished rods or sinker rods with polished rod threads to sucker rods.

All the couplings comply with API Spec 11B and SY/T5029 Standards. There are two wrench flats on the outer circle of couplings. But the wrench flats can be removed per clients' request.

Parameter 1. Material| Material | Chemical Composition (wt%) | |||||||||

| C | Mn | Si | Cr | Mo | Ni | V | S | P | Cu | |

| AISI1045 (45#) | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≦0.25 | -- | ≦0.25 | -- | ≦0.035 | ≦0.035 | ≦0.25 |

| AISI4135 (35CrMoA) | 0.32-0.40 | 0.40-0.70 | 0.17-0.37 | 0.80-1.10 | 0.15-0.25 | ≦0.30 | ≦0.07 | ≦0.025 | ≦0.025 | ≦0.20 |

| AISI5140 (40Cr) | 0.37-0.45 | 0.50-0.80 | 0.20-0.40 | 0.80-1.10 | -- | -- | -- | ≦0.035 | ≦0.055 | ≦0.25 |

| Size (feet) | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | |

| Outer diameter (+0.13, 0.25) | FS | 38.10 | 41.28 | 46.00 | 55.60 | 60.33 |

| SH | 31.80 | 38.10 | 41.30 | 50.80 | 57.15 | |

| Length (+1.57,0) | 101.60 | 101.60 | 101.60 | 101.60 | 114.30 | |

| Counterbore diameter (-0.25,0) | 24.26 | 27.43 | 30.61 | 35.38 | 40.13 | |

| Nominal thread diameter | 15/16 | 1-1/16 | 1-3/16 | 1-3/8 | 1-9/16 | |

| Counterbore depth (+1.588,0) | 11.11 | |||||

| Counterbore depth of polished rod coupling (+1.27,0) | 6.35 | |||||

| Length of spanner square neck | 31.8 | 31.8 | 31.8 | 38.1 | 41.3 | |

| Space between spanner square necks | 34.9 | 38.1 | 41.3 | 47.6 | 53.9 | |

| Cone angle of polished rod coupling | 9° | |||||

| Size (in) | Outer diameter (mm) | Nominal thread diameter (in) | Counterbore diameter (mm) | Length | ||

| Larger end | Smaller end | Larger end | Smaller end | |||

| 5/8×3/4 | 41.28 | 1-1/16 | 15/16 | 27.43 | 24.26 | 101.6 |

| 3/4×7/8 | 46.00 | 1-3/16 | 1-1/16 | 30.61 | 27.43 | 101.6 |

| 7/8×1 | 55.60 | 1-3/8 | 1-3/16 | 35.38 | 30.61 | 127.0 |

| 1×1-1/8 | 60.33 | 1-9/16 | 1-3/8 | 40.13 | 35.38 | 127.0 |

- Instead of cutting, the internal threads are extruded, with a neat surface and high strength.

- The hardness of the couplings is HRA58~62. The hardness of Grade SM is at least HV200.

- The internal and external surface are phosphatized to avoid thread adhesion in operation.