Planetary Concrete Mixer

The planetary concrete mixer is equipped with a motor, a reducing mechanism, a transmission mechanism, a mixing tank, slewing bearings, etc. The mixer is specially designed with higher mixing speed and higher mixing uniformity. The mixing blade features greater abrasion resistance. The concrete mixer is suitable for the production of refractory matter, glass, ceramic and concrete, etc. Our planetary mixer can be used for precast concrete factories, huge buildings, ports, piers and highways.

Both the motor and the reducer are installed vertically, which leads to easy maintenance and cleaning. Elastic coupling and hydraulic coupler are available if customers need. They can protect the transmission mechanism from damage caused by overload. The planetary transmission has a complex movement track, which involves both and revolution rotation. Hence, the planetary concrete mixer achieves strong mixing movement, shorter mixing time, low friction loss and mixing homogeneity. The mixed material won't contact with the transmission mechanism directly, thus eliminating the problem of abrasion and leakage.

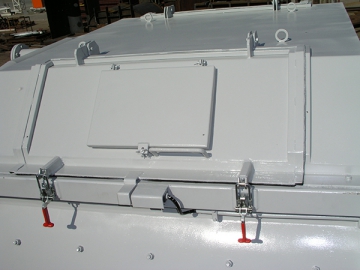

There is a viewing port on the access door for the operators to observe and verify if mixing is properly done without interrupting power supply. This large-size access door leads to easy maintenance and cleaning. We also provide pneumatically or hydraulically controlled discharge door according to customer requirements. Three discharging doors of countercurrent concrete mixer can be opened at the same time. In addition, special sealing device is installed on the discharging door to ensure firm sealing and reliable control.

The spray pipe is equipped with a specially designed spray nozzle to ensure vaporific spraying and large coverage, which further lead to more evenly mixing. High-pressure cleaning device and moisture content meter are also optional.

Technical Parameters| Parameters | Model | ||||||||

| Discharging Capacity (L) | 250 | 330 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Charging Capacity (L) | 375 | 500 | 750 | 1125 | 1500 | 2250 | 3000 | 3750 | 4500 |

| Discharging Capacity (kg) | 600 | 800 | 1200 | 1800 | 2400 | 3600 | 4800 | 6000 | 7200 |

| Mixing Drum Diameter (mm) | 1300 | 1540 | 1900 | 2192 | 2496 | 2796 | 3100 | 3400 | 3400 |

| Rated Mixing Power ( kw ) | 11 | 15 | 18.5 | 30 | 37 | 55 | 75 | 90 | 110 |

| Discharging Hydraulic Power ( kw ) | 2.2 | 2.2 | 2.2 | 2.2 | 3 | 3 | 4 | 4 | 4 |

| Mixing Blade (nr) | 1/2 | 1/2 | 1/2 | 1/3 | 2/4 | 2/4 | 3/6 | 3/6 | 3/9 |

| Scraper Blade (nr) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Drain Separator | --- | --- | --- | 1 | 1 | 1 | 2 | 2 | 2 |

| Weight (kg) | 1200 | 1700 | 2000 | 3500 | 6000 | 7000 | 8500 | 10500 | 11000 |

| Overall dimensions ( L* W * H ) mm | 1570 * 1480 * 1750 | 1862 * 1850 * 1855 | 2220 * 2071 * 1880 | 2550 * 2295 * 2195 | 2893 * 2606 * 2217 | 3223 * 2906 * 2425 | 3625 * 3235 * 2630 | 3893 * 3555 * 2695 | 3893 * 3555 * 2975 |