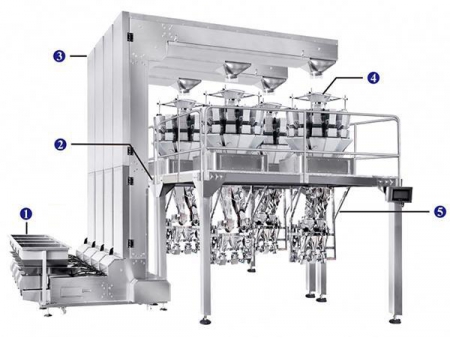

Cup Filling and Capping Line with Automatic Weighing System, 14 Head Weigher

- Vibratory feeder

- Working platform

- Z-shaped elevating conveyor

- 14 heads weigher

- Diverter chute

The cup filling and capping line with an automatic weighing system is composed of a vibratory feeder, working platform, Z-shaped elevating conveyor, 14 heads weigher and diverter chute in order to carry out an accurate filling and fully automatic capping and packing of 2 cups in 1 mold, 3 cups in 1 mold, 4 cups in 1 mold, 5 cups in 1 mold, 6 cups in 1 mold, 8 cups in 1 mold and 10 cups in 1 mold.

Cup types

| Model series | Standard configuration | Maximum cup filling and capping speed (cup/min) | Maximum cup weight |

| 2 cups in 1 mold | Single 14 heads weigher | 80c/min | 800g |

| 3 cups in 1 mold | Single 14 heads weigher | 80c/min | 800g |

| 4 cups in 1 mold | Two 14 heads weigher | 140c/min | 800g |

| 5 cups in 1 mold | Two 14 heads weigher | 140c/min | 800g |

| 6 cups in 1 mold | Two 14 heads weigher | 140c/min | 800g |

| 8 cups in 1 mold | Four 14 heads weigher | 280c/min | 800g |

| 10 cups in 1 mold | Four 14 heads weigher | 280c/min | 800g |

- Check weigher

- Metal Detectors

- Combined metal detector and check weigher

Inserting equipment: Designed to insert small bags of sorbent, desiccant, seasoning mix and more.

Capping device: Add caps to sealed cups- users can choose to add caps individually, or add cap with spoons, seasoning mix bags or other options.

Labeling machine: Attach labels on the cup, you can choose to stick on one side, double sides, circular or other forms.

Diverter chute: Fill your products in multiple dispersing spouts to be ready for more than 1 cup filling, use the 2 cups in 1 mold if you are filling 2 cups at the same time; use 4 in 1 mold if you are filling 4 cups a time, and so on.