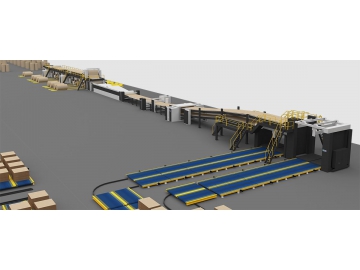

Corrugated Cardboard Production Line

CorrugatedCardboard Production Line

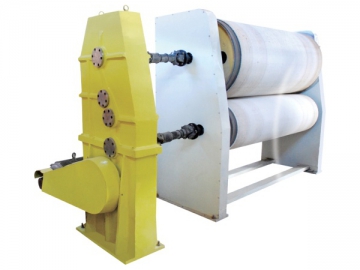

The corrugated cardboardproduction line consists of the following components: raw paper stand,single-roller preheater,single facer, overbridge conveyor, multi-roller preheater,glue coating machine, binding and drying machine (double facer), sheet cuttingmachine, slitter scorer, paper transmitting stand, cross cutting machine,stacking machine, glue making system, electric control system, etc.

Workflow

Firstly, the paper roll shall be sent to the raw paper stand for unfolding,treated with heating and humidity regulating in the single-roller pre-heater ofthe corrugated cardboard production line, and then sent to the single facer forfurther heating, flute pressing, gluing and binding into the single-sidecorrugated cardboard.

Afterwards, the single-side corrugated cardboard shall be pulled onto thetransport overbridge by thelifter for orderly stacking and then for one more time heating in themulti-roller pre-heater of the corrugated cardboard production line and forflute edge pasting in the gluing machine and for cardboard binding and formingtogether with the underlying paper in the binding and drying machine.

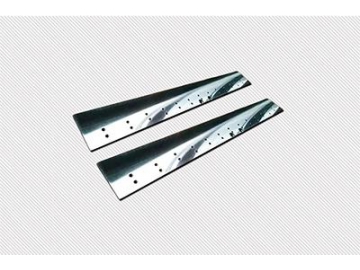

Lastly, the cardboard shall be shaped into pieces of required corrugatedcardboard through precise processing by the slitter scorer and cross cuttingmachine, and then orderly stacked and output by the stacking machine equippedin the corrugated cardboard production line.

As a specialized corrugated cardboard production line manufacturer based inChina, we also provide rotary CNC cutting machine, laminating machine, fullyauto gluing machine, corrugated cardboard double facer, and much more.