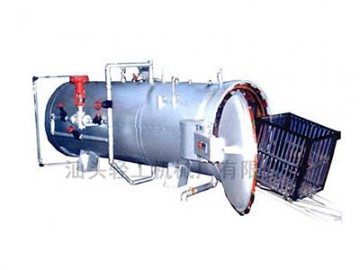

Continuous Hydro Static Sterilizer

Continuous Hydro Static Sterilizer

Continuous hydrostatic sterilizer can be customer-designed according to customer needs. The entire production process from raw material supply, technical design, manufacture, to quality control and onsite installation and debugging is guided, monitored and trained by professional engineers. This sterilizer comes with continuous operation, automatic operation, high safety, energy-saving and environmental protection.

Continuous hydrostatic sterilizer consists of main body, base, operating platform, piping system, control system, and loading and unloading system. The main body includes several different modules, and each module contains several cavities. All the cavities include three parts for heating, sterilization, cooling, respectively. The sterilized products enter following conveying and packaging processes.

- Strong versatility and wide application: the continuous hydro static sterilizer can be used to process products with different containers. The temperature and pressure can be adjusted according to different products, serving different packages with one machine.

- Different sterilization processes are optional, such as water spray, direct steam, etc.

- Compatible with high temperature sterilization and pasteurization

- Fast and timely sterilization: the packaged products enter for sterilization process without waiting.

- Fully automatic operation suits customers with high-volume production needs.

- Low operation cost

- Energy saving

- Low maintenance cost

- Long service life