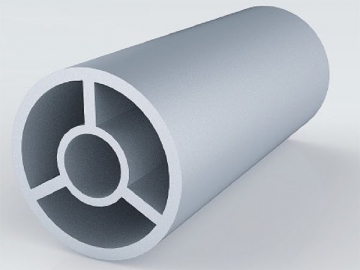

Aluminum Extrusions

With annual production capacity of 500,000 tons, our portfolio includes 100 thousand product types which are divided into over 5000 series. Fenglu is capable of providing innovative aluminum solutions. From mold design and fabrication, aluminum alloy processing, aluminum profile surface finishing through to precise fabrication operations, we have established a complete aluminum production chain and a strict production and operation management system. With more than three decades of experience in aluminum industry, we are able to offer standard and custom aluminum extrusions.

-

Aluminum Design

Aluminum is a strong, light, durable, environmental and design-friendly material. Fenglu has extensive experience in aluminum design and manufacturing. If you are in the early stages of developing a product where you will use aluminium, our technically trained personnel are ready to assist you. We offer guidance on the designs that best suit your application and provide you with detailed advice on matters such as thickness, stresses and surface finish.

-

Extrusion Product Development

Our material and process research, as well as our experience in application development, add value to your business. We offer support from our research and development teams worldwide in your design and product development. Before product development, discuss with our expert team about your requirements. Then, find the best possible solution for your aluminum project – every time.

-

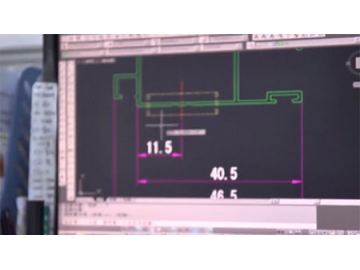

Design and Manufacture of Extrusion Die

Our design engineers are ready to develop the most cost-effective and optimal design for your product, using our custom-made dies. Dies are made of tool steels that are super-hard and abrasion-resistant. This makes them suitable for shaping other materials, like aluminium.

At Fenglu, we make our own dies. We develop design aids for effective extrusion die design, we correct dies to optimize productivity and we research die performance. We keep improving the production process to reduce costs for you, using:

- Material flow simulation in the dies

- Integration with computer-aided design systems

- Heat treatment of tool steels

- Surface treatment of dies with methods such as nitriding, nitrocarburization, chemical vapor deposition and plasma vapor deposition