Filling and Packaging Line for Polyurethane Sealant

Request a Quote

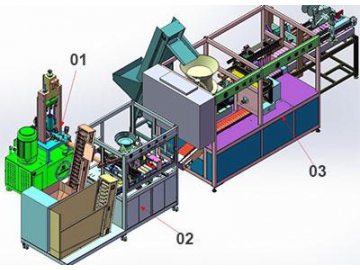

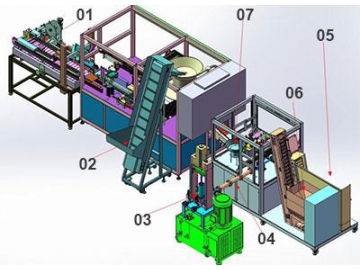

01: 3K static mixer

02: automatic aluminum tube piston filler

03: automatic case erector and sealer

02: automatic aluminum tube piston filler

03: automatic case erector and sealer

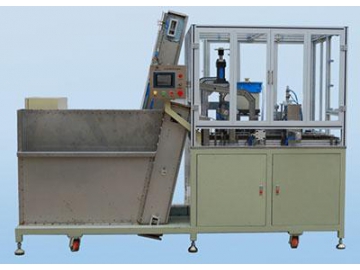

01: Case sealer

02: sealant nozzle storage tank

03: 3K static metering system

04: static mixer

05: aluminum tube load bin

06: plunger load bin

07: granular desiccant feeding device

02: sealant nozzle storage tank

03: 3K static metering system

04: static mixer

05: aluminum tube load bin

06: plunger load bin

07: granular desiccant feeding device

Description

Sample

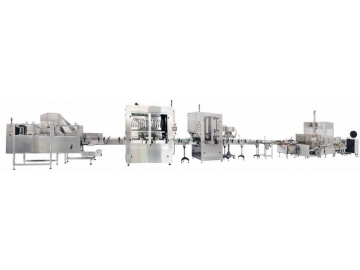

SampleThe Filling and packaging line for polyurethane sealant consists of a 3K static mixer, automatic aluminum tube piston filler, automatic case erector and sealer. And it can be used for the batch production of polyurethane sealant cartridge filling.

Parameters

| Total power | 32KW |

| Gas consumption | 230L/min |

| Filling volume | 240-320ML/cartridges |

| Filling accuracy | ±2g/300ml |

| Output | 400L/hour |

| Casing speed | 1 case/min |

| Color paste proportion | within 8‰ - 8% |

| Additive ratio | within 8‰ - 8% |

| Case size | 5×5 or 4×6 |

| Installation area | 8M (L) ×3.8M (W) |

Note: We can match the voltage and frequency of the equipment depending on customer location.

Features

- The materials loss in traditional sealant producing and filling processes are reduced.

- The workers’ labor intensity is reduced as manual cleaning of the barrels and cylinder is not needed.

- The equipment uses the highest end control system with a combined mode of volume metering and simultaneous squeezing used for static mixing of materials. A flowmeter is added. Pressure sensor is applied for monitoring and detecting. This ensures that the product quality of each cartridge is stable and under the control scope.

Filling process

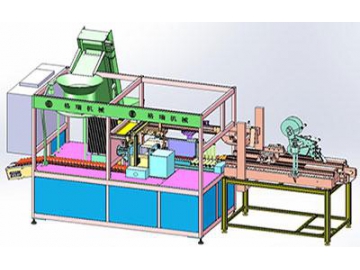

- 3K static mixer blends the base, color pastes and additives evenly by metering mode. Then the mixed product is dispensed by aluminum cartridge piston filler.

- During the operation of aluminum cartridge filler, the 3K static mixer is for mixing and metering, and the filler takes charge of filling, cap inserting, desiccant adding, aluminum cap ring seaming and coding to dispense the products.

- After being transferred by the device, the product will be installed with a sealant nozzle by case erector and sealer. The products will be stacked in the case based on customer demands.

- Place label and qualification. Seal the case and affix security label. Then the casing is finished.

Related products

Send Message

Most Recent

More

Other Products

Videos