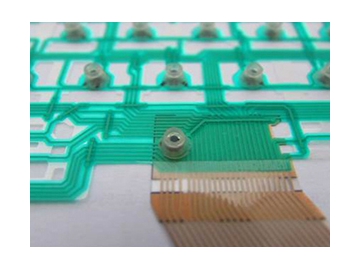

- Printing requirement: line width ≤0.2mm, spacing between= 0.2mm;

- Testing requirement: loop resistance<250Ω;

- Membrane switch connector requirement: pinch ≤0.2mm. Bending test pass≥10 times.

- Circuit hardness test: ≥2H.

- Silver circuit adhesive force test: no peel off after being pulled by the 3M600 tape.

- Environment test: high temperature, high humidity 70°*95%RH*96hrs, low temperature -40℃*96hrs, high low temperature 25℃*50%RH~0℃~-40℃*2hrs~65℃*90%RH*2hrs~-40℃5CYCLES;

- Free Ag test: 65℃*90%RH*240hrs*5V DC;

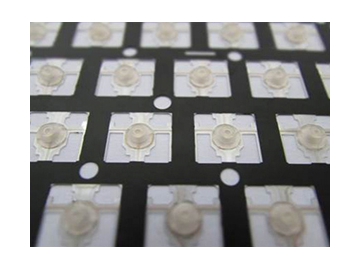

- Operational life requirement: 10 million operations min.

After the above tests are carried out, embrittlement and break or short circuit should not occur, while the circuit resistance should be smaller than 300% of the original resistance. The layout circuit requires a wire width of ≤0.3mm and the spacing between ≤0.25mm.

Excellent insulating properties for the circuit are necessary. Jumping wire designed need to be reduced as much as possible to decrease membrane thickness.