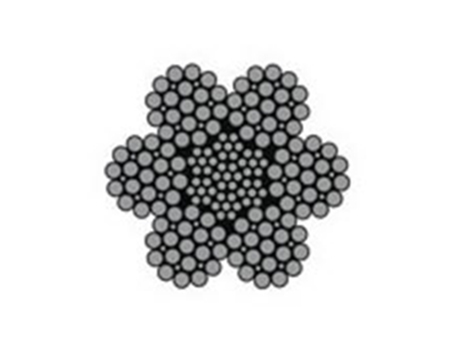

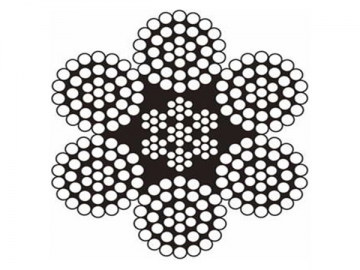

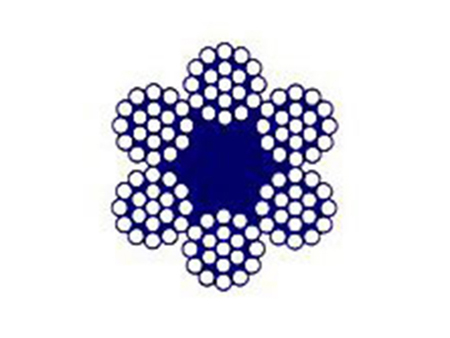

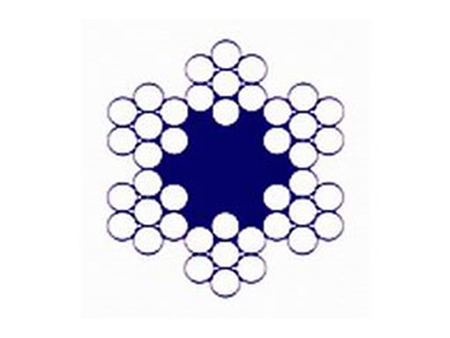

6X19 Classification Bright Wire Rope, IWRC (Steel Core)

Instruction

The bright steel wire rope is a wire rope with oiled or oil-free surface. To prevent rust, the twisted steel wires are treated with oil-impregnated treatment. While entwisting the small steel wires, a pulley enters into the oil pool, and then moves to the wire rope axle. After that, those entwisted steel wires will be made into a wire rope with the same method. Generally, this bright wire rope serves as hoist rope.

Product Specifications

Name: Wire Rope -6X19 Classification

Structure: 6×19+IWRC

Diameter: 6 ~ 46mm

Tensile Strength: 1570N/mm2 ~ 1870 N/mm2

Standard: ASTM, DIN, GB, EN12385-4

Application: It is used to cranes, excavators, winches, wire rope slings, etc. It is also widely used in the oil fields.

Package: Wooden or plastic tray, carton, wooden box

Features: It is most durable in the place where environment conditions are controllable. 6×37 series is more flexible than 6×19 series.

| Nominal Diameter | Approximate Weight | Nominal Tensile Strength | |||||||||

| 1570 | 1670 | 1770 | 1870 | ||||||||

| mm | In | Kg/100m | Minimum Breaking Strength | ||||||||

| FC | IWR | FC | IWR | FC | IWR | FC | IWR | FC | IWR | ||

| 6 | 1/4 | 12.5 | 13.7 | 17.3 | 18.7 | 18.4 | 19.9 | 19.5 | 21.1 | 20.6 | 22.3 |

| 7 | 9/32 | 17.0 | 18.7 | 23.6 | 25.5 | 25.1 | 27.1 | 26.6 | 28.7 | 28.1 | 30.4 |

| 8 | 5/16 | 22.1 | 24.4 | 30.8 | 33.3 | 32.8 | 35.4 | 34.7 | 37.6 | 36.7 | 39.7 |

| 9 | 3/8 | 28.0 | 30.9 | 39.0 | 42.2 | 41.5 | 44.9 | 44.0 | 47.5 | 46.5 | 50.2 |

| 10 | 13/32 | 34.6 | 38.1 | 48.1 | 52.1 | 51.2 | 55.4 | 54.3 | 58.7 | 57.4 | 62.0 |

| 11 | 7/16 | 41.9 | 46.1 | 58.3 | 63.0 | 62.0 | 67.0 | 65.7 | 71.1 | 69.4 | 75.1 |

| 12 | 1/2 | 49.8 | 54.9 | 69.4 | 75.0 | 73.8 | 79.8 | 78.2 | 84.6 | 82.6 | 89.4 |

| 13 | 1/2 | 58.5 | 64.4 | 81.4 | 88.0 | 86.6 | 93.7 | 91.8 | 99.3 | 97.0 | 104.0 |

| 14 | 9/16 | 67.8 | 74.7 | 94.4 | 102.0 | 100.0 | 108.0 | 106.0 | 115.0 | 112.0 | 121.0 |

| 16 | 5/8 | 88.6 | 97.5 | 123.0 | 133.0 | 131.0 | 141.0 | 139.0 | 150.0 | 146.0 | 158.0 |

| 18 | 11/16 | 112.0 | 123.0 | 156.0 | 168.0 | 166.0 | 179.0 | 176.0 | 190.0 | 186.0 | 201.0 |

| 20 | 13/16 | 138.0 | 152.0 | 192.0 | 208.0 | 205.0 | 221.0 | 217.0 | 235.0 | 229.0 | 248.0 |

| 22 | 7/8 | 167.0 | 184.0 | 233.0 | 252.0 | 248.0 | 268.0 | 263.0 | 284.0 | 277.0 | 300.0 |

| 24 | 15/16 | 199.0 | 219.0 | 277.0 | 300.0 | 295.0 | 319.0 | 312.0 | 338.0 | 330.0 | 357.0 |

| 26 | 1 | 234.0 | 258.0 | 325.0 | 352.0 | 346.0 | 374.0 | 367.0 | 397.0 | 388.0 | 419.0 |

| 28 | 1-1/8 | 271.0 | 299.0 | 377.0 | 408.0 | 401.0 | 434.0 | 426.0 | 460.0 | 450.0 | 486.0 |

| 30 | 1-3/16 | 311.0 | 343.0 | 433.0 | 469.0 | 461.0 | 498.0 | 489.0 | 528.0 | 516.0 | 558.0 |

| 32 | 1-1/14 | 354.0 | 390.0 | 493.0 | 533.0 | 524.0 | 567.0.0 | 556.0 | 601.0 | 587.0 | 635.0 |

| 34 | -- | 400.0 | 440.0 | 557.0 | 602.0 | 592.0 | 640.0 | 628.0 | 679.0 | 663.0 | 717.0 |

| 36 | -- | 448.0 | 494.0 | 624.0 | 675.0 | 664.0 | 718.0 | 704.0 | 761.0 | 744.0 | 804.0 |

| 38 | 1-1/2 | 500.0 | 550.0 | 695.0 | 752.0 | 740.0 | 800.0 | 784.0 | 848.0 | 828.0 | 896.0 |

| 40 | 1-19/32 | 554.0 | 610.0 | 771.0 | 833.0 | 820.0 | 887.0 | 869.0 | 840.0 | 918.0 | 993.0 |

| Nominal Diameter | Approximate Weight | Minimum Breaking Loads - 1770 Mpa |

| [mm] | [kg/m] | [kN] |

| 14 | 0.780 | 124.00 |

| 16 | 1.050 | 161.30 |

| 18 | 1.320 | 204.00 |

| 20 | 1.610 | 252.00 |

| 22 | 1.940 | 305.00 |

| 24 | 2.390 | 363.00 |

| 26 | 2.780 | 426.00 |

| 28 | 3.210 | 494.00 |

| 30 | 3.750 | 567.00 |

| 32 | 4.200 | 645.00 |

| 34 | 4.780 | 728.00 |

| 36 | 5.350 | 817.00 |

| 38 | 5.950 | 910.00 |

| 40 | 6.550 | 1008.00 |

| 42 | 7.350 | 1112.00 |

| 44 | 7.920 | 1220.00 |

| 46 | 8.750 | 1333.00 |

| 48 | 9.650 | 1452.00 |

Related Names

Load Cable | Wire Rope Sling | Steel Cables