Experiences of Sheet Metal Fabrication

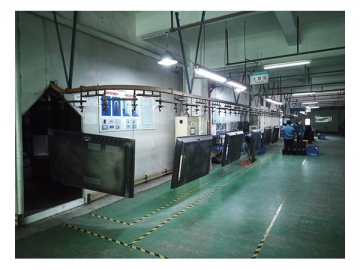

Jiatong specializes in short to large run precision sheet metal fabrication for equipment used in food service, telecommunications, gaming, electronics and medical industries. We fabricate sheet metal parts for diverse customer base including OEMs and contract manufacturers. We have all of the necessary equipment and experts to carry out high-quality sheet metal cutting, stamping, forming, bending, welding and finishing assembly services.

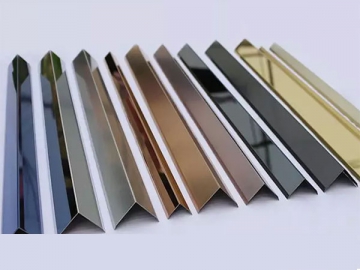

One of our specialties is the fabrication of thin gauge sheet metal generally between 0.1 - 6mm thick. We commonly process materials like aluminum sheet, stainless steel, SECC and SPCC etc. The following are some of our previously made sheet metal mechanical parts and assembled products.

This product is a large, thick enclosure designed to house and protect sophisticated technology. When the customer contacted us, they let us know their requirements regarding processing equipment, factory environment, scale, and quality control documents. After inspection and certification, they recognized our processing capabilities and decided to have us produce samples.

When manufacturing the samples, we found that the stress deformation is large after welding because of the size and thickness, and thus it will affect the assembled effect. In order to solve this problem, after repeated communication with our customer’s engineer, we decided to add leveling technology to ensure the surface of our products is smooth. We used an array of welding technology and we found some lead to surface deformation. Therefore, we decided to change the former welding method to subsection welding and it decreased the probability of deformation and cracking.

Customer feedback: the printer enclosure we processed for them has no deformation problems and we have collaborated for three years.

In 2016, a customer from Israel found us and they needed a large-scale integrated control equipment enclosure. The product was large and needed high surface precision and strict surface processing.

Difficulty: the enclosure adopted an integrated structure and the interior shield needed to prevent power spillage and leakage. Meeting these requirements through normal processing methods would be difficult and many other manufacturers told the customer they couldn’t get the job done.

Solutions: after communicating with our technicians, we decided to employ “shield before welding” technology, and thus the problem has been solved.

Feedback: our customer was satisfied with our products and we have cooperated in sheet metal processing after this equipment enclosure production.

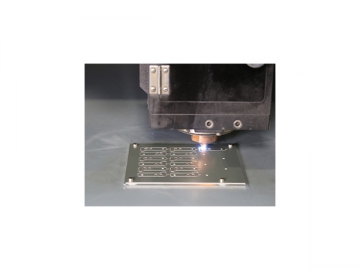

A well-known Japanese printer and copier manufacturer found us to produce internal sheet metal components. The product would be a new type and has a complicated structure.

Customer requirement: save the cost and decrease the weight of the product.

Solutions: if we apply the general procedure for die production, the whole cost is about six hundred thousand RMB and the production cycle need to be 8-10 weeks. But according to the actual situation and negotiating with our customer, we decided to employ a simple die processing method in the stage of sample and small batch production. After three tests, we met the design requirements and the time would be less than 3 weeks while the whole cost is less than 150 thousand RMB. Our customer was satisfied with the time and cost savings.

A well-known copier and printer manufacturer in the united states found us looking for processing of internal core support sheet metal components for their copier equipment. The products needed to be high precision and had strict requirements regarding the surface. When we first began communication, they were worried about the quality of the products but after detailed evaluation, they decided to inspect some samples we produced. They confirmed that the products met their requirements and the products were put into mass production.