Pulp and Paper

Since most of the pipeline mediums in pulp and paper industry are filter slurry and contain fibers and solid materials, the valves in this industry should have high wear resistance, reliable sealing, good erosion and plugging resistance and be easy to switch. And it’s necessary to solve the strong corrosion of chlorine dioxide in bleaching sections. When using ordinary valves, the valve will be wear seriously and needs to change frequently, which brings inconvenience for production.

Titanium alloy valves act as a very suitable solution for the harsh working conditions of paper industry. Over the years, we have produced various titanium segment ball valves, titanium knife gate valves and other products for different customers in the paper industry. Based on our rich experience in papermaking industry and the professional knowledge of our technical department, we have the ability to formulate the best valve selection scheme according to your specific needs to ensure the stability of the system.

Chlorine dioxide bleaching system of Asia Symbol

- Project time: 2012-2017

- Customer location: Shangdong, China

- Customer requirements: Used in pulping section to transport pulp containing chlorine dioxide and medium containing sulphuric acid. Medium temperature: 0-100 ℃

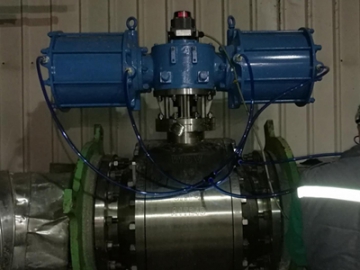

- Valves used: Titanium segment ball valve, DN400 ball valve with pneumatic actuator, check valve