Showroom

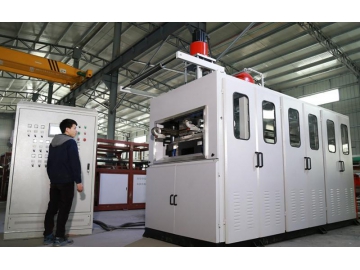

Shantou Elite Machinery is a specialized manufacturer of disposable thermoforming equipment. We produce sheet extrusion machines, cup making machines, plastic cup stacking machines, and counting and packing machine lines.

The Elite factory is located in Shantou City, Guangdong, China. The production facility covers an area of 6000 square meters and here we independently carry out the design, assembly, and testing of our high quality equipment. We also have the ability to offer customized equipment based on the specific needs of customers.

A Thai client owns the largest milk tea shop chain in Thailand. We began working together in 2014 and since then, they have purchased 9 sets of SLSE120-900A sheet extrusion machines and 20 sets of CMM750-520BA cup making machines.

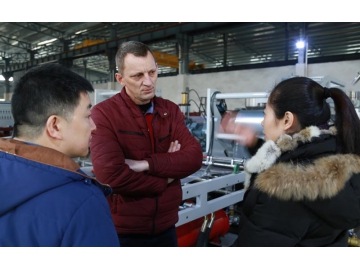

In January 2018, a customer from Croatia came to the factory to pick up finished equipment. The customer ordered our SLSE120-900E sheet extrusion machine, CMM750-520BA cup making machine and the matched custom molds.

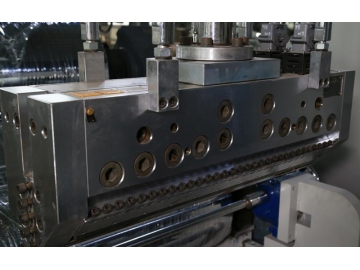

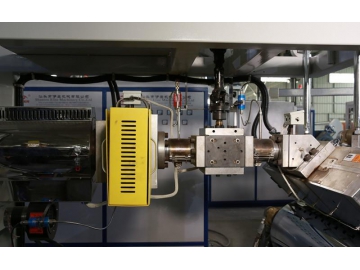

The extrusion die can be adjusted in a push-pull manner, which not only is convenient to operate, but also can guarantee uniform thickness of the extruded sheet.

The measuring pump can precisely adjust the flow of the plastic, and the screen exchanger can ensure a uniform flow of plastic so as to achieve the effective control of the sheet thickness.

After 38CrMoAlA nitrogen treatment, the high quality screw has a rigidity up to 900-1000HV to ensure the plasticizing effect and a long service life of the screw.

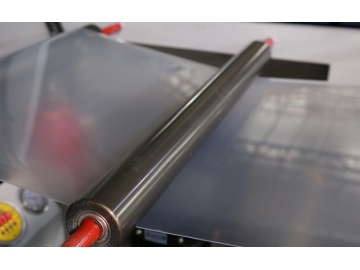

The aluminum guide roller is used for the transition and cooling of the sheet to create a smooth surface. It will not cause any scratches on the sheet's surface.

Three-rolled calendar provides an outstanding cooling effect for the larger roll surface.

The flip winding system, used for winding sheet, has a soft power to avoid the occurrence of sheet cracking, so it is even suitable for winding thin sheet.

The hydraulic winding system is used for winding sheet roll with each roll weighing up to 1.5 tons.

The sheet extrusion machine and cup making machine all adopt Siemens PLC with touch screen control, featuring full automation, safe, easy operation and simple maintenance.

Thorough machine inspection

Thorough machine inspection Thorough machine inspection

Thorough machine inspection Power distribution cabinet inspection

Power distribution cabinet inspection Electrical and program testing

Electrical and program testing

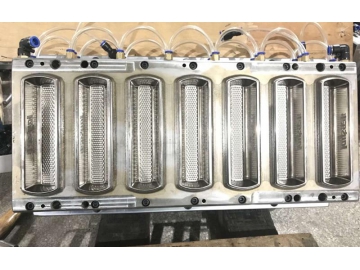

Elite Machinery can customize molds used in manufacturing plastic products according to the agreed upon sample and machine model specifications. The manufacturing period lasts around 60 to 90 working days. The following are some of the finished products we have delivered to clients.

Elite employs a professional after-sales department to ensure that the problems the customers meet during the production process can be solved in a timely manner.

The technical team leader, a senior engineer with many years of experience in mechanical production and debugging, is personally involved in the design and production of each machine. We not only focus on the quality and production of the machine, but also consider the operation to ensure our machine design is safe and easy to use.