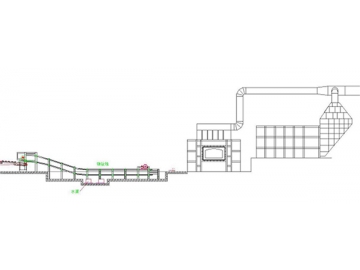

Slab Rolling Conveyor of Continuous Casting System

Request a Quote

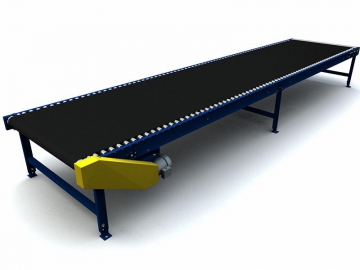

After the casting billet is straightened, it is transferred by a roller table for manual flame cutting. When the billets are cut into originally calibrated sizes, the billet segments are delivered by the rolling conveyor to billet exit roller table. The rolling conveyor system is made up of several roller racks, arranged with free roll, billet exit rolling device and billet exit roller bed on it. Each free roll or billet exit roll is driven by its own motor and reducer through the sprocket and chain. Finally, the slab is transferred to the fixed position by rolling conveyor.

Related products

Send Message

Most Recent

More

Other Products

Videos