Small Hole EDM Drilling

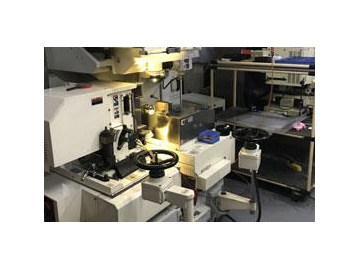

Most EDM drilling machines are CNC-controlled, however, some are actually mounted on the table of a CNC mill. By retrofitting an EDM driller onto a CNC mill, Yinchuang offers micro hole and small hole EDM drilling services on parts over 2,200 lbs and in excess of 40" long. Size and weight are rarely a restriction when popping or drilling fast, small holes at Yinchuang.

+/- 0.001” TOLERANCE:Typical tolerance but can vary due to type of material.

0.004” TO 0.25” DIAMATER HOLES:KLH stocks a variety of single and multi-channel tube configurations.

41” X 19” x 23” WORK ENVELOPE:The non-submersible drillers have virtually no limits in the X- & Y-axis.

BURR-FREE HOLE:Spark erosion process leaves clean holes ready for the medical industry.

ALL CONDUCTIVE MATERIAL:Drills soft or hard metals, graphite, carbide, and polycrystalline diamond.

ELECTRODE TOOL CHANGER:Uninterrupted production EDM drilling up to 16 electrodes and 4 different sizes.

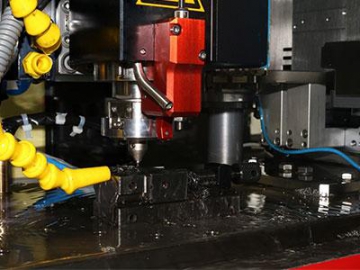

Small hole EDM drilling uses the EDM principal of spark erosion to burn fast, micro holes into electrically conductive material. Unlike sinker EDM, which uses custom electrodes, small hole EDM drilling uses a brass or copper tube as an electrode. As the charged electrode is lowered into the work piece, a spindle rotates the tube to evenly distribute electrode wear, remove debris, and assure uniform roundness.