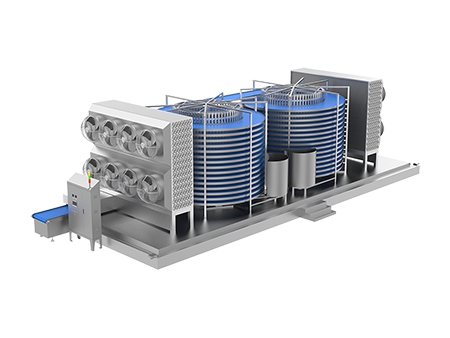

Spiral Freezer

Model: SF01

Our spiral freezers can be tailored to suit your specific requirements. Our focus on details enables us to optimize the spiral freezer/cooler for a complete line of applications, from raw dough to fully baked, ready-to-eat meat and poultry products. The spiral freezer can be made with food grade stainless steel and plastic.

- Key Features

- Food Grade plastic belting

- Tensile strength up to SCH40

- UHMWPE wear strip

- Conform to the Highest Standards

- FDA & AIB sanitation standards

- OSHA safety standard

- CE, UL certificate

- Key Features

- SS304 spiral conveyor belting

- Open profiles and fully welded structure in product zone

- High strength for long lifespan up to 30 years

- High freezing capacity up to 20t/h

- Conform to the Highest Standards

- FDA & AIB sanitation standards

- OSHA safety standard

- CE, UL certificate

| Max. freezing capacity | 1000kg/h |

| Frozen product | Chicken Nuggets |

| Product size | 50*50 *30mm |

| Product weight | 25gm |

| Holding time range | 20-60mins, adjustable |

| Inlet temperature | 65°C (180°F) |

| Outlet temperature | -18°C |

| Evaporating temperature | -40°C |

| Air temperature | -31°C |

| Freezer enclosure dimension | 7100*4100*5300 |

| Number of Tiers | 24 |

| Tier pitch | 150mm |

| Net tier pitch | 80mm |

| Belt width | 508mm |

| Usable belt width | 450mm |

| Total belt length | 300m |

| Infeed / outfeed height | 900mm / 4780mm |

| Refrigeration system | 172kW of cooling at -40°C |

| Type of refrigerant | R717 |

| Evaporator defrost method | Water |

| Power consumption | 20.5kW |

Our spiral freezers are designed based on our many years of experience in freezing and manufacturing techniques. The complete spiral freezer will be preassembled at the factory and disassembled in sections for shipping purposes. Therefore, the spiral freezing system can quickly be reassembled at the job site. Our simple and practical spiral freezer design with robust construction ensures many years of trouble free operation.

- Counter-flow airflow for efficient heat transfer

- Axial flow fan provides horizontal air flow for better heat transfer for all surfaces of the product. Optimum airflows effectively transfer heat away from your product.

- Coil tubes for liquid supply are regulated by orifices to equalize pressures on each tube, maximizing heat transfer with minimum liquid feed.

- A fully welded spiral formwork eliminates hidden cleavages for bacteria at product zone, providing ease of wash down.

- Freezer formwork, tier carriers, spiral cage, air baffles and shafts are made of food grade stainless steel, ensuring maximum sanitation and long service life.

- Designed with sloped surfaces for ease of wash down and drainage.

- Features high-efficiency fans and motors, evaporators with large surface areas.

- The spiral freezing system can be custom made to efficiently handle a wide range of production capacities.

- Modular design for easy and quick on site installation.

- Main frame

- Belting

- Drive system

- Evaporator

- PLC control system

- Insulated wall

- Axial flow fan

- Sequential defrost system

- CO2 refrigerant system

- Thermal steam system

- Fully automatic CIP cleaning system (option)

You can contact us for a quotation or with any questions you may have on this product.