Two-piece Can Production Line

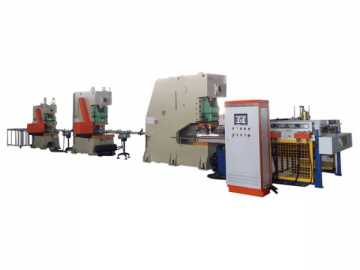

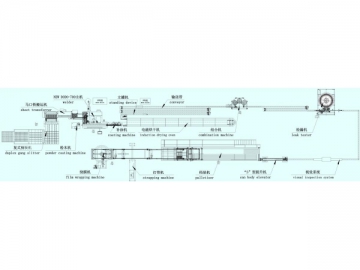

Shantou Light Industrial Machinery Factory customizes two-piece can (integral body and base plus a lid) production lines. We design, construct, install, and maintain fully integrated two-piece canbody production lines that operate at low speed all the way up to 500 cans per minute.

Two-piece cans serve as an alternative to three-piece cans. The two-piece can is a packaging container with the bottom end and body shaped from a single piece of deep drawn metal. Its second end is sealed to form an airtight package.

- No seam between the body and the bottom end, so the can is tightly sealed while using fewer raw materials.

- The can body can be decorated and printed upon and two-piece cans require less metal, making them lighter and cheaper.

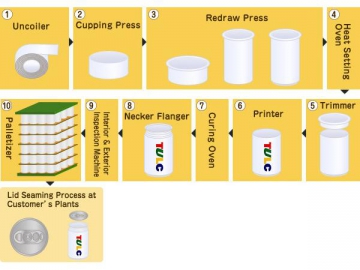

- The can making process is easy and efficient.

Producing two-piece cans requires high performance materials and equipment.

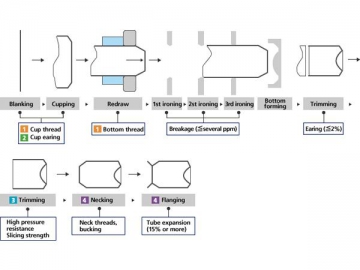

Types of two-piece cans:Categorized according to body height, there are shallow drawn cans and deep drawn cans; by raw materials, you can make two-piece aluminum cans and steel cans (tinplate cans); in terms of can body forming, there are drawn and ironed (DI) cans and drawn and redrawn (DRD) cans; by can shapes, there are round cans and irregular cans. The most commonly used types are DI cans and DRD cans.