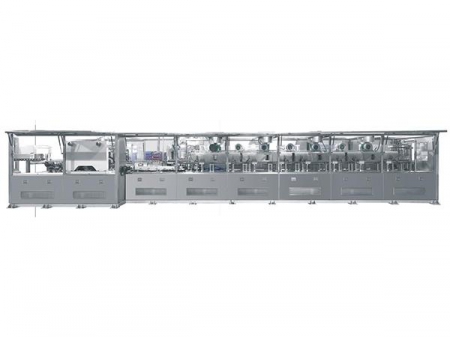

400KN Bottle Blowing Machine

Application

The Timey 400KN PET bottle blowing machine is designed for the production of plastic bottles used for carbonated beverages, mineral water, cosmetics, cooking oils, and even medicines.

Parameter

| Usable material | PP PET PS PC AS PETG Etc. |

| Clamping force | 400KN |

| Stretching stroke | 400MM |

| Bottom stroke | 15MM |

| Cavity quantity | 2 |

| Capacity | 400-1800 P/H |

| Max. heating power | 60KW |

| Heating power | 20KW(Normal production) |

| Motor power | 0.18KW |

| Operation pressure | 8KG/CM2 |

| Blowing air | 1 M3 7.5kw/H |

| Weight | 1600KG |

| Dimension | 2835*1500*1940 |

| Max. bottle volume | 1200ML |

| Neck diameter range | 90MM |

| Max.container diameter | 90MM |

| Max.container height | 270MM |

Features

1. The control system of the bottle blowing machine features a PLC provided by Mitsubishi. This system allows the machine rapid responsiveness, high accuracy and optimal reliability. These features improve the quality of the machine as well as operational safety.

2. The high-pressure blow valve of the blowing machine is a Lucifer model produced by Parker. It can withstand 40kg pressure. This allows the machine to run with accuracy and reliability as well as extend its overall service life.

3. The machine can be outfitted with a loading bottle manipulator as well as a downloading bottle manipulator in order to realize fully automated operation.

4. Energy efficiency is one of the main features of this machine and the compact structure is one of the factors that adds to its efficient operation.

We offer plastic machines for manufacturing PET bottles and plastic containers. Our 400KN bottle blowing machine is suitable for making PET bottles, polypropylene bottles, polystyrene bottles, polycarbonate bottles, AS bottles, PETG bottles, etc. We have all the production resources to make plastic bottle blowing machines with custom made service, offering quality machines for making carbonated drink bottles, water bottles, cosmetic bottles, cooking oil containers, pharmacy bottles.