Automatic Scraper Centrifuge

Featuring continuous operation and intermittent discharge, the GK(F)/GKC automatic scraper centrifuge is mainly used for solid-liquid separation. It is controlled by a PLC (programmable logic controller), and it uses a frequency converter to regulate its work speed and adopts a braking system to realize dynamic braking or regenerative braking.

With fill level control, speed inspection as well as shaft temperature and vibration monitoring, our horizontal scraper centrifuge is able to finish the entire separation process automatically, from suspension filling, dry centrifugation, washing to final discharging. Manual operation is also available.

Main Characteristics of GK(F) Automatic Scraper Centrifuge

1. This horizontal pharmaceutical centrifuge has a completely sealed and leakproof structure, and its housing is perfectly welded to make it robust yet lightweight.

2. All the process steps, including filling, initial filtering, washing, secondary filtering and discharging, are strictly monitored to help operators better control the solid-liquid separation process.

3. The automatic air exchange system is configured according to oxygen content or protective gas pressure.

4. The inner surface of our automatic scraper centrifuge is well polished without any dead angle, and a CIP (Cleaning In Place) system is employed to clean final product and process area easily. In addition, our patented automatic residual heel removal system is optional.

5. As for discharging, a discharge chute or a screw conveyor is used.

6. Our horizontal centrifuge not only fits for solid-liquid separation of medium and fine particle suspension, but also fits for toxic, explosive and combustible products, making it commonly used for the separation of raw materials, intermediate products and end products in pharmaceutical and chemical industries.

| Model | ||||||||

| Basket diameter (mm) | 800 | 1060 | 1250 | 1250 | 1350 | 1600 | 1600 | 1800 |

| Basket depth (mm) | 400 | 500/630 | 500 | 630 | 680 | 800 | 1000 | 1000 |

| Basket volume (L) | 100 | 210/260 | 290 | 380 | 500 | 700 | 840 | 1061 |

| Loading capacity (kg) | 135 | 230/280 | 370 | 500 | 650 | 900 | 1000 | 1320 |

| Max. speed (r/min) | 1500/1600 | 1400/1700 | 1200 | 1200 | 1200 | 950 | 950 | 900 |

| Max. separating factor | 1007/1145 | 1150/1696 | 1006 | 1006 | 1086 | 808 | 808 | 815 |

| Motor power (kW) | 30 | 37/55 | 55 | 55 | 55 | 90 | 90 | 132 |

| Machine size with shock absorber (mm) | 2215 ×2000 ×2100 | 3191 ×2100 ×2140 | 2745 ×2200 ×2620 | 2745 ×2200 ×2620 | 3860 ×2500 ×2900 | 4625 ×3100 ×3430 | 4625 ×3100 ×3430 | 5640 ×3600 ×3900 |

| Machine weight without platform (kg) | 3200 | 6000/6200 | 7000 | 7600 | 8500 | 14000 | 14800 | 22700 |

| Machine weight with platform (kg) | 6000 | 14000/ 14200 | 14500 | 15600 | 16000 | 31000 | 31800 | 40500 |

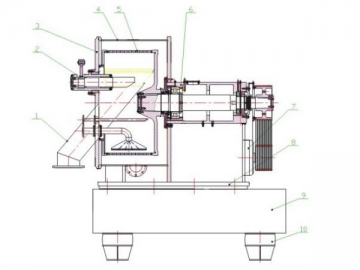

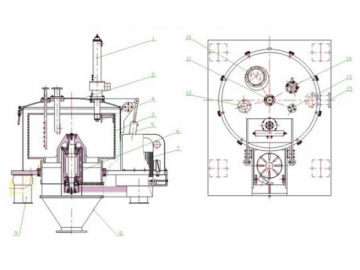

| 1. Discharge Chute 2. Scraper 3. Housing | 4. Cover 5. Basket 6. Bearing Seat | 7. Transmission Parts 8. Base Plate 9. Floating Platform 10. Shock Absorber |

Main Characteristics of GKC Automatic Scraper Centrifuge

1. Due to its totally enclosed structure and inertisation system, this pharmaceutical scraper centrifuge is especially suitable for working in explosion proof conditions, and its power area and process area are absolutely isolated to avoid contamination.

2. Our automatic scraper centrifuge is fitted with a CIP system so as to realize thorough cleaning to prevent cross contamination, and its housing can be opened to facilitate inspection and cleaning of the internal parts.

3. Thanks to gas pressure pulses generated by the back flush device, all residual heels are removed completely.

4. This bottom discharge centrifuge is installed through the wall, and it fully conforms to GMP, CGMP and FDA requirements for pharmaceutical applicatio

| Model | |||||

| Basket diameter (mm) | 800 | 1000 | 1050 | 1250 | 1350 |

| Basket depth (mm) | 400 | 500 | 500 | 630 | 660 |

| Basket volume (L) | 100 | 180 | 210 | 335 | 450 |

| Loading capacity (kg) | 130 | 230 | 230 | 430 | 585 |

| Max. speed (r/min) | 1500/1800 | 1400 | 1400 | 1200 | 1200 |

| Max. separating factor | 1007/1448 | 1096 | 1150 | 1006 | 1086 |

| Motor power (kW) | 30 | 37 | 37 | 55 | 55 |

| Machine size with shock absorber (mm) | 2620×2000 ×2070 | 3439×2316 ×2428 | 3439×2316 ×2428 | 3700×2500 ×2700 | 3860×2680 ×2740 |

| Machine weight with platform (kg) | 9800 | 15000 | 16000 | 18000 | 20000 |

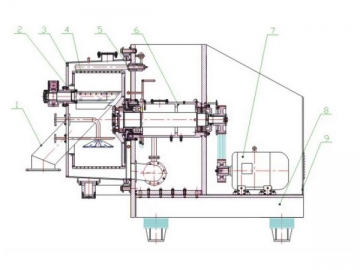

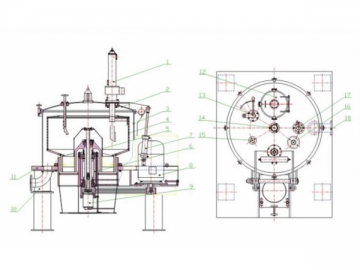

| 1. Discharge Chute 2. Scraper 3. Housing | 4. Basket 5. Back Flush Device 6. Bearing Seat | 7. Transmission Parts 8. Floating Platform 9. Enclosure for Drive System |