Diamond Calibrating Roller

Request a Quote

The diamond calibrating roller, also referred to as a diamond calibrating wheel, is a common diamond tool used for calibrating and leveling the surface of ceramic and porcelain tiles. These polishing and calibrating tools need to be used with cooling water and deliver high polishing efficiency for a smooth surface finish.

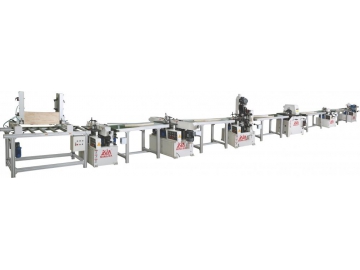

Examples of Application- Applicable machine types: calibrating machine, tile polishing machine, etc.

- Tiles processed: porcelain tiles, vitrified tiles, crystal tiles, floor tiles, wall tiles, etc.

- Tile sizes: 600x600, 800x800, 1000x1000, 600x1200, 300x300, 300x600, etc.

Working Condition: Water Cooling

| Length (mm) | Out Diameter (mm) | Spirals | Segment Size (mm) | Grit |

| 300 400 595 645(585) 800(740) 800(680) 995(935) 1195(1135) 1600(1540) | Ф180~ Ф 320 | 5/6/7/12/16 | 9x12 9x15 6x10 | 30 40 50 60 70 80 100 120 140 |

Notes: Depending on the matched machines, the diamond calibrating roller can be individually designed and produced.

Characteristics- The diamond calibrating wheel is designed with spiral finish, allowing for quick heat dissipation.

- The calibrating roller features a stock removal rate of 36m/min and a processing area of 17500m2 for processing polished tiles.

- Monte-Bianco can design and manufacture the diamond calibrating rollers based on the features of processed tiles and matching equipment.

Related products

Send Message

Most Recent

More

Other Products

Videos