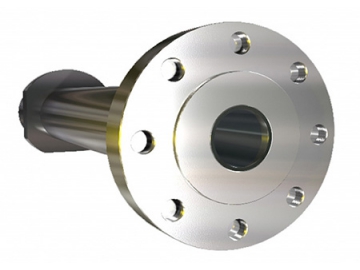

Extrusion Barrel

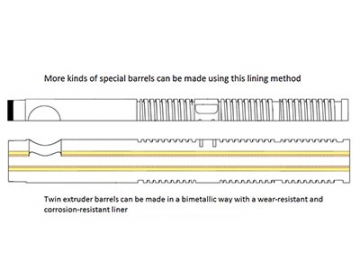

Omega offers customization of extrusion barrels made using different materials. For a single screw extruder, we offer whole extrusion barrels and barrel liners. Not only do we recommend the best barrel materials to meet different manufacturing conditions, but we are also excellent at manufacturing bimetal barrels with a higher wear resistance and longer working life.

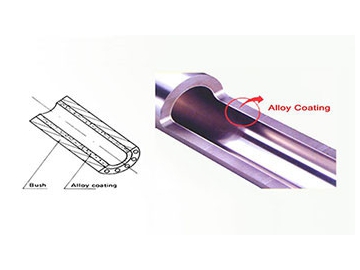

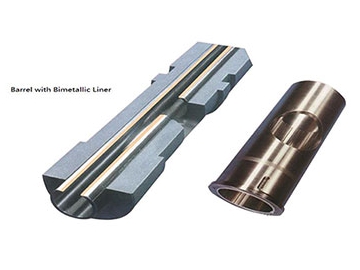

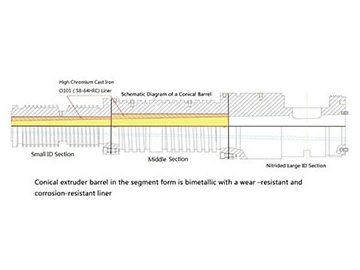

The bimetal barrel has a basic body material with normal strength, but there are specific alloy layers on the surface of the bore in barrel. We can change the thickness and toughness of this layer, and make it wear resistant or corrosion resistant, or both wear resistant and corrosion resistant. The basic body material and corresponding alloy layer form a whole, called bimetal barrel.

Ω201

| Properties | Ω101 | Ω201 | Ω301 | |

| Wear Resistance | ★★★ | ★★ | ★★★ | |

| Corrosion Resistance | ★ | ★★★ | ★★★ | |

| Main Elements | Fe-Ni-B | Ni-Co-Cr-B | Fe-Cr-Ni-B-Carbide | |

| Hardness (HRC) | 58~64 | 50~56 | 55~65 | |

| Breaking Strain (%) | 0.30 | 0.24 | 0.20 | |

| Elastic Strain (kgf/mm) | 18600 | 215000 | 22000 | |

| Coefficient of Thermal Expansion(/℃) | 15℃~250℃ | 10.0×10-6 | 11.9×10-6 | 11.2×10-6 |

| 15℃~400℃ | 10.5×10-6 | 12.6×10-6 | 11.9×10-6 | |

The chief leading member of our Shanghai Omega Group is the first creator in the bimetallic technology in the last century 80 's in China, researching and developing different kinds of alloy protective coatings for the bimetallic barrel and bimetallic screw. After years of constant exploration and improving, it’s proven that the bimetallic barrel and bimetallic screw protected by different kinds of wear-resistant and corrosion-resistant alloy feature excellent operation life and unmatched cost-performance. Our research and development is highly praised by the industry, and has made a significant contribution to the industry development.

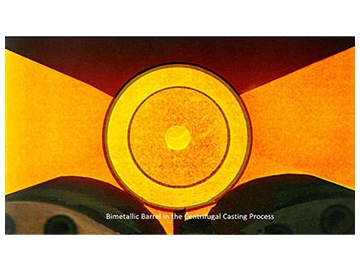

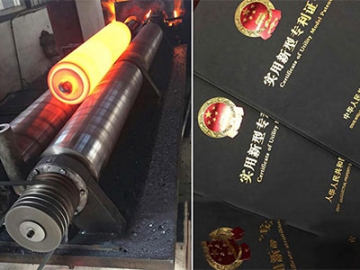

Our diesel injection furnace and centrifuge equipment for bimetallic cylinder molding are under a national patent protection, see below:

These equipment sets protected by national patents, coupled with the special process we have always adhered to, have guaranteed the proportion of hard phase inside the alloy layer and the hardness of the alloy layer of bimetallic cylinders produced by our company, are always stable and higher than other suppliers in China who mimic the bimetallic barrel technology created by our company.