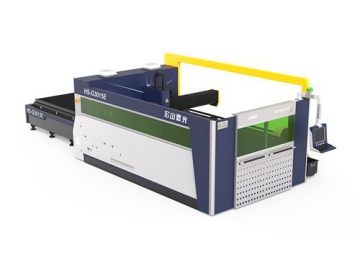

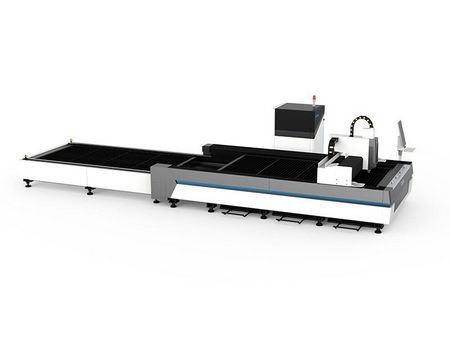

G3015E Fiber Laser Cutting Machine with Protective Cover

Equipped with an interchangeable table, the G3015E fiber laser cutting machine can process both metal sheets and tubes. The maximum cutting speed is 60m/minute, and it is safe to operate due to its protective cover structure.

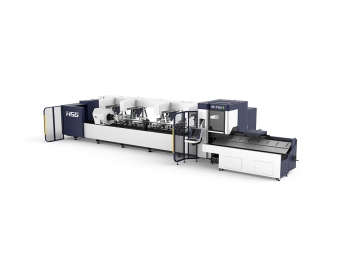

1. For pipe cutting

Applicable materials: Not only can it cut 0.5-5mm carbon steel pipe or the stainless steel pipe, but the pipe cutter can also process other pipe materials, such as aluminum, brass, copper, galvanized steel, cold rolled steel and more.

Applicable size: 20×20mm-150×150mm square tube, Φ20-Φ219mm circular tube

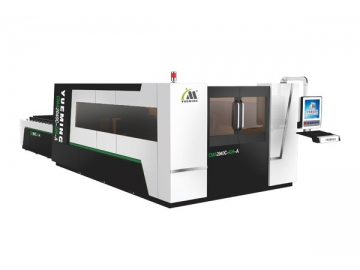

2. For sheet cutting

0.5~16mm carbon steel sheet, 0.5~8mm stainless steel sheet, 0.5~6mm brass, 0.5~4mm copper galvanized sheets as well as electrolytic board and silicon steel

3. Application industries

This cutter is applicable to sheet metal processing, office furniture, kitchenware, hotel supplies, food machinery, shelves and more.

| Processing Area | 3000mm×1500mm (optional) |

| Laser power | 500W-3000W(optional) |

| Max. moving speed | 60m/min |

| Max. acc. speed | 0.5G |

| Positioning Accuracy | 0.05mm/m |

| Reposition Accuracy | ±0.05mm |

| Power Supply | 380V/50Hz |

| Whole machine weight | 8500kg |

| Sheet Machine dimensions | 8500mm×3650mm×2100mm |

| Tube Machine dimensions | 4450mm×900mm×1050mm |

- We can customize machines for tube cutting with a processing width of 3m or 6m.

- We can customize machines for sheet cutting with a processing width of 3m×1.5m, 4m×2m, or 6m×2m.

- We can customize special machine models for cutting angle steel, steel I-beam and more.

- We offer lasers with various powers. Material and thickness to be cut are both dependent on the laser power.

- Stainless steel

- Carbon steel

- Brass

- Copper

- Aluminum

- Galvanized steel

- Cold rolled steel

- Titanium

- Electrolytic steel

- Silicon steel

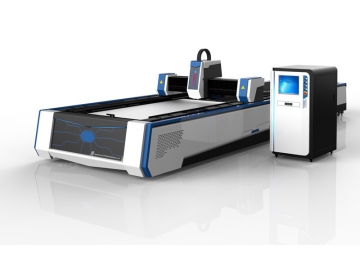

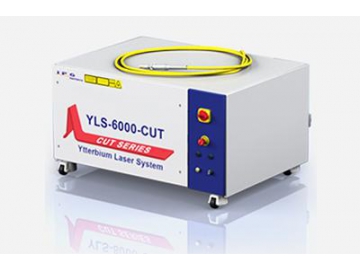

- Laser systemA powerful fiber laser system from IPG.

- High rigidity bedThe metal bed on this cutter has undergone a heat treatment of 600°C and is cooled inside the furnace afterwards for 24 hours. After it has cooled, it is processed using a plano milling machine and welded using carbon dioxide. This gives the cutter its strength and service life of 20 years.

- Servo motorThe electric and drive systems provided by Japan Sanyo Denki offer customers a faster rotation speed and better stability.

- Transmission systemHSG LASER uses a rack and pinion from ALPHA. This rack and pinion will not get stuck and stop, and can be paired perfectly with the cutter.