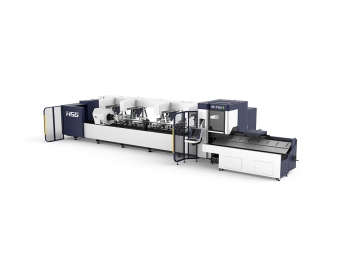

HC Series Electro Hydraulic Servo Bending Machine

Request a Quote

Bending Samples

Technology parameter

| Name | Parameter |

| Bending force | 1100KN |

| Table length | 4100mm |

| Table height | 900mm |

| Distance between columns | 3500mm |

| Throat depth | 400mm |

| Slider stroke | 200mm |

| Opening height | 470mm |

| Fast descending speed | 180mm / s |

| Return speed | 140mm / s |

| Working speed | 10mm / s |

| Back gauge (X axis) travel | 0-600mm |

| X-axis positioning accuracy | ± 0.05mm |

| X axis repeat positioning accuracy | ± 0.02mm |

| Y-axis positioning accuracy | ± 0.02mm |

| Y-axis repeated positioning accuracy | ± 0.01mm |

| R axis travel | 150mm |

| Working accuracy | Straight: ± 0.2mm / m, Angle: ± 0.5 °mm / m |

| Number of CNC axes | 4 1 axis |

| main motor power | About 7.9KW |

| Fuel tank capacity | 400L |

| Dimensions (length × width × height) | 4650 × 1580 × 2680mm |

| Equipment weight | About 10200KG |

Remarks

The Y axis includes: Y1 and Y2 axes—NC axes that control the up and down movement of the two main oil cylinders to control the bending angle;

X axis—A numerically controlled axis that controls the back and forth direction of the back gauge to control the bending size;

V axis-mechanical deflection automatic compensation axis, used to compensate the deformation of the table and the slider under load;

R axis—A numerically controlled axis that controls the up and down direction of the back gauge, which can be used to control the bending of uneven-sized workpieces

Advantages

- CybTouch 12PS Control System from CYBELEC (Switzerland brand)

- The control system of HC series servo bending machine adopts Switzerland (CYBELEC) CybTouch 12PS control system for superior performance

- Easy single bending with 2D graphic programming "EasyBend" page

- Automatic calculation of bending data, bending angles, main pressure and deflection compensation

- Correct the angle and back gauge range

- Fully efficient bending programming makes bulky production come true.

- Deflection Compensation WorkbenchCompensate for deflection deformation caused by workbench, using processing program to calculate the compensation automatically according to the length, thick and angle of bending workpiece.

- Post-positioning SystemBack gauge range system: move back and forth (X axis), move up and down (R axis) all driven by servo motor, configured with 4 positioning fingers.

- Servo MotorAdopt servo motor instead of asynchronous motor as the main power source of hydraulic pump, and retain the proportional valve control technology, which is mature and reliable. Its servo-controlled variable pump can significantly reduce machine tool noise and oil heat, and save energy consumption by 40% .

Related products

Send Message

Most Recent

More

Other Products

Videos