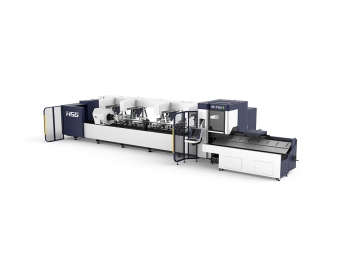

HB Series Oil-electric Hybrid Bending Machine / Hybrid Press Brake

Request a Quote

Introduction

HB series hybrid bending machine provided by HSG Laser is a new generation press brake features energy saving, low noise and steady.

This bender adopts dual-servo motor to control the oil pump directly for fast braking speed, realizing a significant increase in production efficiency. Besides, the servo motor can stop work if flow or pressure is unneeded, which reduces noise and energy consumption.

Another benefit is the low heat balance temperature lowers the risk of oil leakage, no need for cooling device, or traditional bulky oil tank. The service life of hydraulic system and oil cylinder improved greatly because of high stability.

Bending Samples

Technology parameter

| Press capacity | 2200KN |

| Maximum bending length | 4040mm |

| Distance between the frames | 3340mm |

| Throat depth | 450mm |

| Height of lower worktable | 950mm |

| Stroke length | 180mm |

| Opening height | 470mm |

| Number of cylinders | 2 |

| Oil volume | 70L |

| Weight of whole machine | About 13100Kg |

| Power | About 17KW |

| Size | About 4560×1755×2700mm |

| Item | Speed | Precision |

| Y1, Y2 axis - go down | 150mm/s | / |

| Y1, Y2 axis - bending | 0.2-50mm/s | ±0.01mm |

| Y1, Y2 axis – go up | 150mm/s | / |

| X-axis - front and back | 500mm/s | ±0.01mm |

| Z1, Z2 axis - left and right | 700mm/s | ±0.1mm |

| R axis - up and down | 60mm/s | ±0.1mm |

Advantage

- DSVP-based Oil-electric Hybrid SystemThis bender adopts dual-servo motor to control the oil pump directly for fast braking speed, realizing a significant increase in production efficiency. Besides, the servo motor can stop work if flow or pressure is unneeded, which reduces noise and energy consumption. Another benefit is the low heat balance temperature lowers the risk of oil leakage, no need for cooling device, or traditional bulky oil tank. The service life of hydraulic system and oil cylinder improved greatly because of high stability.

- High-rigid Frame and Automatic Deflection CompensationHigh-rigid frame is optimized in shape and can improve the entire bending accuracy based on calculated Y value and accurate workbench positioning. The angle tolerance of bending workpiece is ±30’; Through programming, the automatic deflection compensation system can calculate compensation automatically according to the length, thick and angle of the bending workpiece, in addition, match with inverse deformation while boosting pressure.

- Efficient and Reliable Post-positioning SystemPosition after high-speed movement, X-axis: 500mm/s, Z-axis: 700mm/s, R-axis: 60mm/s; length measured on X-axis: 600mm;

High positioning accuracy, X-axis: ±0.01mm, Z-axis: ±0.1mm, R-axis: ±0.1mm.

Note: Only applicable to HB1003/HB6020

- Various Upgrade SolutionsAdd automation interface to enable automation upgrade whenever necessary, and make bending simpler and faster.

Intelligent CNC System, High Running Rate

- Built-in CAM SystemThe CNC system uses well-designed graphs (Windows TM style) and equipped with advanced 3D functions. It is a real CAM system (Italian STEP).

- Automatic Saving, Data SharingThe system supports multiple file format import, offer keyword-based retrieval and accept production instructions through bending plan function. Settings such as the order of bending and mold layout can be edited and saved. Note function is added for processing cautions noting and sharing. Processing information can be saved and the data is shared after processing.

- Humanized Screen, Easy OperationHumanized screen supports special molds display. The functions of simulation and mold positioning & guiding are optimized for easy operation. Length compensation is available and easy. Processing is done based on 3D simulation.

Related products

Send Message

Most Recent

More

Other Products

Videos