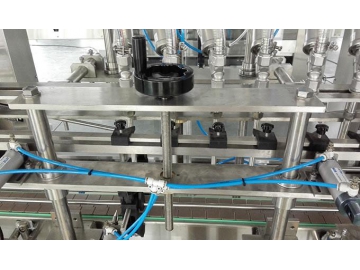

50-1000ml Liquid Filling Machine (for Low-Viscosity Liquid), ZGP-16H

The 50-1000ml liquid filling machine for low viscousity liquid bottles containers that are less than 1000ml in volume. With precise and accurate filling, the liquid filling machine processes food sauces and condiments such as soy sauce, vinegar, syrup and cooking oil as well as cosmetic and chemical liquids such as ES and SL. Made of stainless steel, the bottle filling machine has an easy to use touch screen and PLC control panel.

- Capacity: ≤6000 bottles/hr (100ml water as medium)

- Bottles: Dimensions Φ33-100mm, Height 80-280mm

- Volume: 50-1000ml

- Precision: ±1%

- Air pressure: 0.6MPA

- Power source: ~220V

- Power: 1.5KW

- Material Feeding Connector: DN32 Flange

- External Dimensions: 2300 x 710 x 2200mm (L x W x H)

- Weight: about 650Kg

- Production line height: 900mm±50mm

- Bottle feeding direction: From left to right

1. Controlled speed and position of the filling nozzle reduces foaming. Adjustable settings for filling volume, filling time, filling heads, bottle sizes and production capacity.

2. Optimized bottle-in and bottle-out control modes for increased production capacity.

5. The material level sensor checks the level of liquid with alarms for too high or too low levels. Filling heads equipped with a bottle-mouth-clamping device to ensure accurate filling and no overflow. Precision control within ±1%.

6. A liquid holder controlled by an individual cylinder is installed under the filling nozzles to prevent unwanted material from entering the bottles.

7. Made of stainless steel 304 to prevent corrosion. Glass door prevents pollution. Connecting pipe parts are easy to install for convenient cleaning and maintenance.

8. Angle seat valve imported from Burkert Valves in Germany for precise and reliable filling.

| Model | ZGP-6H | ZGP-8H | ZGP-10H | ZGP-12H | ZGP-16H |

| Dimensions | 2000 x 710 x 2200mm (L x W x H) | 2200 x 710 x 2200mm (L x W x H) | 2300 x 710 x 2200mm (L x W x H) | ||

| Filling head | 6 | 8 | 10 | 12 | 16 |

| Capacity ( 1L) | 1800B/H | 2000 B/H | 2800 B/H | 3200 B/H | 4500 B/H |

| Power | 1KW | 1 KW | 1KW | 1.5KW | 1.5KW |

| Type of bottle | Diameter : Φ 33mm --Φ 100mm Height : 80mm -- 280mm | ||||

| Filling accuracy | ≤100ml : -1.5ml 100-500ml : -2ml 500-1000ml : -3ml | ||||

| Neck diameter | 18mm | ||||

| Filling range | 50ml--1000ml | ||||

| Air pressure | 0.6Mpa | ||||

| Power supply | 220V; 50HZ | ||||

| No. | Item | Supplier | Brand |

| 1 | Touch screen | Taiwan | WEINVEIW |

| 2 | PLC | Japan | Mitsubishi |

| 3 | Photo sensor for bottles | Japan | OPTEX |

| 4 | Solenoid valve | Taiwan | SHAKO |

| 5 | Level button | USA | JOHNSON CONTROLS |

| 6 | Angle seat valve | Jointed | BURKERT |

| 7 | Other devices | Taiwan | Airtac |

| 8 | Power button | France | Schneider |

| 9 | Button | France | Schneider |

| 10 | Frequency converter | France | Schneider |

| 11 | Bottle-transport motor | China | Huangyan |

| 12 | Speed reducer | China | Jiao xing |

| 13 | Relay | Japan | Omron |