Single Screw Extruder for Ceramic Membrane

Request a Quote

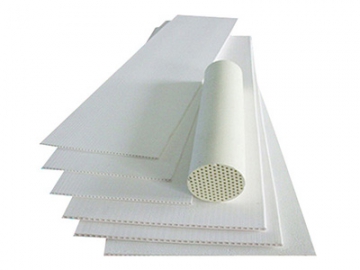

The single screw extruder for ceramic membranes is used to make ceramic membrane plates.

Ceramic Membrane Plate

Ceramic membrane plates are a hyper filtration membrane that is able to remove impurities like suspended solids and microorganisms in liquid. Ceramic membrane plates feature a 3-5 times longer working life, 50% lower chemicals / energy consumption and 50% lower maintenance cost when compared to polymetric membranes.

Products after extrusion process

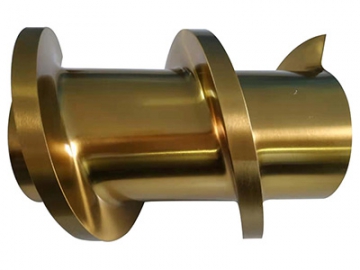

Products after extrusion process PM-HIP extrusion screw

PM-HIP extrusion screw Extrusion screw with functional coatings

Extrusion screw with functional coatings

Details of design

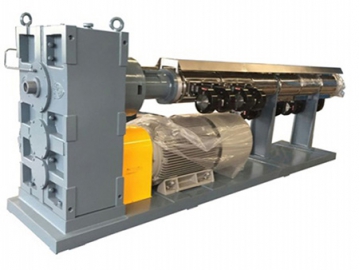

- Motor / Reducer

We use the high torque variable frequency motors (VFDs) with a cooling unit for our one-stage and two-stage extruders. The motors can save energy and function in a stable manner, ensuring the extruders feature a long service life.

In addition, our compact design ensures these machines save space. - Torque distribution system

We use high quality Japan NSK bearings as the radial bearing. - Gears

The gears are made of 20CrNi2MOA,HRC58-62 metal, which features an extraordinarily high abrasion resistance. - Extrusion Barrel

A water-cooling system is used outside the barrel, ensuring the machine works smoothly. - Control Cabinet

The touch screens and PLC (Programmable Logic Controller) have been put in the control cabinet.

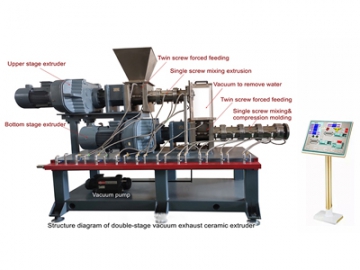

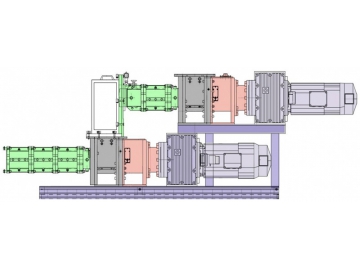

Construction Drawing

Parameters

| Items | One Stage Compacting Extruder | Two stages compacting forming extruder |

| Hopper | 304 stainless steel, manual feeding | Vacuum feeding |

| Main Motor | 11 kw | 18.5 kw |

| Diameters (mm) and materials of the Screws | ⌀117.5, Quench hardened martensitic stainless steel | ⌀117.5, Quench hardened martensitic stainless steel |

| Screw length / diameter (L/D) | 8 | 10 |

| Screw Speed (rpm) | 5~30 rpm | 5~30 rpm |

| Ultimate screw pushing force (Mpa) | 10 Mpa | 18 Mpa |

| Max. screw torque at highest speed (Nm) | 6600 | 11000 |

| Power of variable frequency motors | 11 kw | 18.5 kw |

| Vacuum exhaust system | Germany Busch motors, Motor Power 0.75 kw,Ultimate Vacuum 0.1 hPa (mbar), Max. speed 1800 rpm, Max. Pumping rate 30 m3/h | |

| Temperature control type of the barrel and the screw | Water circulation cooling outside the barrel | Water circulation cooling outside the barrel and inside the screw |

| Range of temperature control of the barrel and the screw | 10℃~100℃ | 10℃~100℃ |

| Range and accuracy of temperature of raw materials | 50℃±0.2 | 50℃±0.2 |

| Levels of barrel temperature | 3 different levels | 5 different levels |

| Back pressure of raw materials | 3 Mpa | 15 Mpa |

| Screw hight of center (mm) | 1700 | 1100 |

| Output of Al2O3 with density of 4.0 g/cm3 | 160 kg~280 kg/hr | |

| Total installed capacity (kW) | 41 | |

| Power Consumption under normal operation (%) | 80% | |

| Dimensional size (mm) | Length, 3500 × Width, 1100 × Height 2000 | |

| Whole weight of the machine (kg) | 2500 | |

Related products

Send Message

Most Recent

More

Other Products

Videos