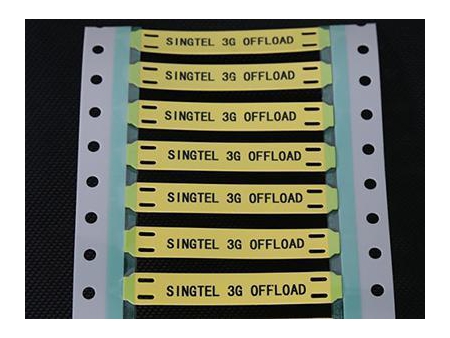

Cable Marker Tags

Request a Quote

Model: CYG-MT(TAG)

Material: Radiation-crosslinked modified polyolefin

Application

Printable cable label and wire markers, with a product ID of CYG-MT (TAG), is designed to meet the high performance identification requirements for cable manufacturers and is used in environmental temperature ranges of - 40 ℃ to 125 ℃. The print material meet the requirements of SAE-AS-81531MIL-STD-202F standards, and the raw material is resistant to organic solvents, such as fuel oil. After being tightly tied with nylon ties, the label maintains its print performance, even after long term usage.

| Part | Size(W x H) in mm | Effective print area in mm |

| CYG-MT(TAG)-45 x 10.4 | 45 x 10.4 | 25 x 10.4 |

| CYG-MT(TAG)-70 x 20.3 | 70 x 20.3 | 50 x 20.3 |

Remarks: other sizes are upon the request

Performance index| Item | Test methods | Specifications |

| Tensile Strength | SAE-AMS-DTL-23053 | ≥10.3MPa |

| Ultimate Elongation | SAE-AMS-DTL-23053 | ≥200% |

| Flexibility | SAE-AMS-DTL-23053.4.6.7 | -55℃±1℃, 4h, No cracking |

| Heat Shock at 250℃±3℃ at 4hrs | SAE-AMS-DTL-23053.4.6.8 | 250℃±3℃, 4h, No cracking, dripping, flowing |

| Aging Performance | SAE-AMS-DTL-23053.4.6.9 | 175℃±2℃, 168h, No visual damage |

| Tensile Strength After Aging | SAE-AMS-DTL-23053.4.6.13 and ASTM D638 | ≥6.9MPa,23℃±2℃ |

| Ultimate Elongation After Aging | SAE-AMS-DTL-23053.4.6.13 and ASTM D638 | ≥100%,23℃±2℃ |

| Color Stability | SAE-AMS-DTL-23053.4.6.15 | 175℃±2℃, 24h, Pass |

| Dielectric Strength | SAE-AMS-DTL-23053.4.6.13 and ASTM D2671 | ≥19.7kV/mm,23℃±2℃ |

| Volume Resistance | SAE-AMS-DTL-23053.4.6.13 and ASTM D876 | ≥1.0x1014Ω· cm,500V (DC),60s |

| Flammability | UL224 | Flame resistance |

| Fluid Resistance | AE-AMS-DTL-23053.4.6.11 | No visual damage |

| Print Persistence | SAE-AS-81531.4.6.2 | 50 rubber erasure , identification |

| Print Solvent Resistance | MIL-STD-202G Method 215K | 10 rubber erasure , identification |

Remarks: other sizes and colors are available upon request.

Specifications| Item | Test methods | Specifications |

| Physical performance | ||

| Operation temp. | - 40 ℃ to 125 ℃ | |

| Tensile strength (M Pa) | ASTM D2671 | ≥10.3Mpa |

| Ultimate elongation ratio (%) | ASTM D2671 | ≥200% |

| Flexibility (-55℃, 4hrs) | ASTM D2671 | No cracking |

| Heat shock at 250℃±3℃ at 4hrs | ASTM D2671 | No cracking, dripping, flowing |

| Electrical performance | ||

| Dielectric strength | ASTM D2671 | ≥19.7kV/mm |

| Volume Resistance | ASTM D876 | ≥1014Ω·cm |

| Flammability | UL224 | Flame resistance |

| Fluid resistance (23℃,24hrs) | ASTM D2671 | Print identified |

| After Aging at 175℃±2℃ at 168hrs | ||

| Tensile strength (M Pa) | ASTM D2671 | ≥6.9Mpa |

| Ultimate elongation ratio (%) | ASTM D2671 | ≥100% |

| MIL-M-81531-4.6.2 | 20 rubber erasure, identification | |

| Print performance | ||

| UL 224, | 50 Rubber erasure, identification | |

| MIL-M-81531-4.6.2 | 50 Rubber erasure , identification | |

| MIL-STD-202 | 30 Rubber erasure, identification | |

- Excellent oil resistance.

- Non shrinkable, and we provide different lengths of nylon tie according to different customer requirements.

- Print performance meets SAE-AMS-DTL-23053/5 requirements.

- Various product packaging methods to meet different customer requirements

- Can be printed with a standard dot matrix printer or heat transfer printer.

- Readable with single-side printing

- Product color can be customized, but standard colors of white or yellow

- Great print persistence without any additional steps.

- Meets the requirements of SAE AS815 31.4.6.2 MIL-STD-202 METHOD215J precision standards for aviation and railways and industrial standard ASTMD2671.