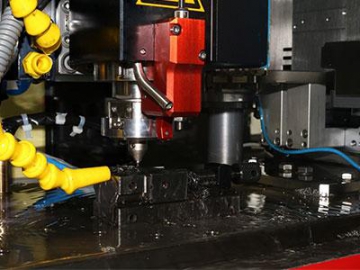

EDM Machine Control System Kits

Manufacturers of EDM machines can purchase C-TEK EDM machine control systems and EDM machine control system kits to form their own fully functional EDM machines with higher precision and a better performance. In addition, upon request, C-TEK can add the customer company's logo on the control panel.

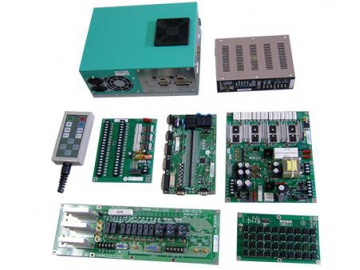

C-TEK has CNC EDM machine control system kits and ZNC EDM machine control system kits.

The CNC EDM machine control system kits includes a position control box, a CNC PC box, three DC servo driver, a discharging board, a standard resistor plate, a machine connecting board, a keyboard, a CNC MPG remote control box, a volt-meter, a am-meter and a current sensor.

The ZNC EDM machine control system kits include a ZNC PC box, a DC servo driver, a discharging board, a keyboard, a ZNC remote control box, an IO plate, a standard resistor plate, a volt-meter, an am-meter and a current sensor.

If the machining current is over 150A, you need to select a heavy-current resistor plate and an expanded resistor plate. If the machining current is over 100A, you need to select a high frequency rectifier board and an expanded discharging board.

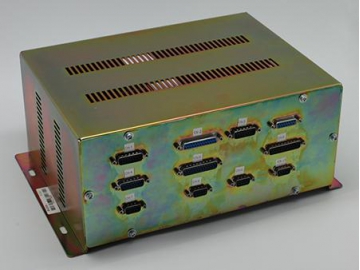

The position control box is used for the position control of the CNC EDM machine.

The position control box is used for the position control of the CNC EDM machine. An IO plate is used for IO signal processing of ZNC EDM machine.

An IO plate is used for IO signal processing of ZNC EDM machine. AC servo adapter plate is used to process the signal of the AC servo driver.

AC servo adapter plate is used to process the signal of the AC servo driver. ZNC/CNC machine connecting board for the machine body.

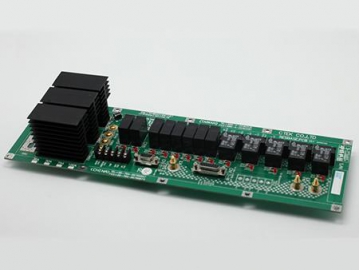

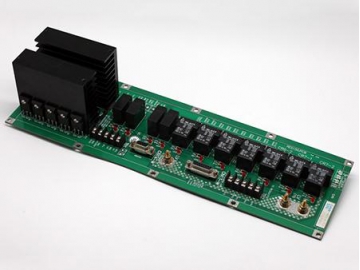

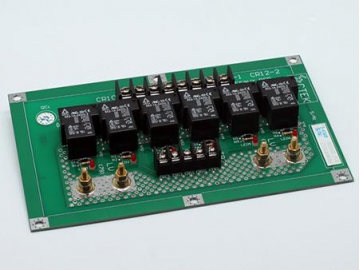

ZNC/CNC machine connecting board for the machine body. Resistor plate is used to control current selection. If the machining current is under 100A, you must use this resistor plate.

Resistor plate is used to control current selection. If the machining current is under 100A, you must use this resistor plate. If the machining current is over 100A (include 100A), you must use expended high frequency discharging.

If the machining current is over 100A (include 100A), you must use expended high frequency discharging. The CNC MPG remote control box is designed for the CNC EDM machine. With an MPG calibrate mold function, the machine can be operated more easily.

The CNC MPG remote control box is designed for the CNC EDM machine. With an MPG calibrate mold function, the machine can be operated more easily. A heavy-current resistor plate is used to control heavy-current selection. If the machining current is over 150A, you must use this heavy-current resistor plate.

A heavy-current resistor plate is used to control heavy-current selection. If the machining current is over 150A, you must use this heavy-current resistor plate. A heavy-current resistor plate is used to control heavy-current selection. If the machining current is over 150A, you must use this heavy-current resistor plate.

A heavy-current resistor plate is used to control heavy-current selection. If the machining current is over 150A, you must use this heavy-current resistor plate. DC servo driver adopts PWM control loop. With +/-10V INPUT,TG+/-7V and a supply voltage of AC110V/AC35~60V, the DC servo driver can control the DC servo motor with power of 100W~500W.

DC servo driver adopts PWM control loop. With +/-10V INPUT,TG+/-7V and a supply voltage of AC110V/AC35~60V, the DC servo driver can control the DC servo motor with power of 100W~500W. High frequency discharging board makes control more stable, so the machine will be unlikely to malfunction. It is fully paralleled. If the machining current is under 75A (include 75A), you should use high frequency discharging.

High frequency discharging board makes control more stable, so the machine will be unlikely to malfunction. It is fully paralleled. If the machining current is under 75A (include 75A), you should use high frequency discharging. A tungsten processor is used for the CNC tungsten EDM machine. With the tungsten processor, the CNC tungsten EDM machine can process super-hard material better. The processing speed can be several times higher and the electrode consumption can be significantly reduced.

A tungsten processor is used for the CNC tungsten EDM machine. With the tungsten processor, the CNC tungsten EDM machine can process super-hard material better. The processing speed can be several times higher and the electrode consumption can be significantly reduced.