CNC EDM Machine

Request a Quote

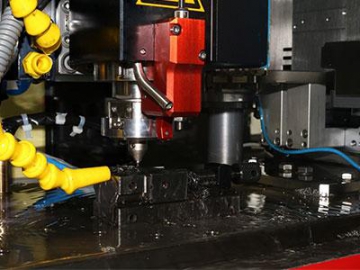

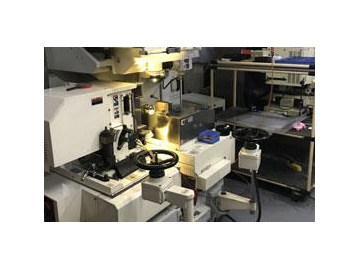

The X, Y and Z axis of the CNC die sinking EDM/ die-sink EDM/sinker EDM are all computer controlled so users can set differently shaped processing paths. The CNC die sinking EDM is especially suited for processing workpieces with complex shapes.

Features

- Auto storage function delivers a capacity of 100*40000 configurations.

- Molds can be processed for everything from rough modeling all the way through to finished products.

- 10 fine processing functions.

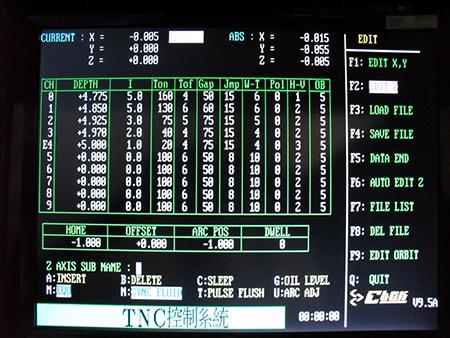

- (1) Manual editing: edit the machining condition by experience.

- (2) AUTOZ auto editing: max. Depths, initial current and finished procession, machining area selection are provided, and machining condition editing can be finished automatically.

- (3) FUZZY Z intelligent condition editing: electrode shape, electrode and work piece material, work piece section area and finished precision selection, depth setting areas are provided, and then machining condition editing is completed automatically.

- Five orbit processing patterns. One mold can be set by 5 different orbit processing patterns.

- More than 1000 units of document storage capacity are provided. I.e. more than 1000 different molds or customers can be assigned a number.

- Auto correction of electrode consumption. During multi-hole processing, electrode consumption shall be preset, and then the computer can automatically correct the depth of each hole to make sure they have uniform depth.

- Quick compensation through auto finding of the molds’ central point.

- When the condition for discharging is unstable, the computer will correct the discharging efficiency and working time automatically. After stabilizing all conditions, the discharging will continue automatically. Processing conditions can be adjusted at any time.

- Auto return to zero for base point: should there be any loss of power during auto-processing, the computer can find the base point automatically;

- With a mirror surface processing circuit, a true mirror effect can be achieved.

- JMP UP1 Speed up servicing to improve the processing efficiency without distorting electrode;

- Orbit and side processing: Cross, Square, Round, Hexagonal, side sparking;

- English/Chinese Dialogue Operation, all processing data can be input easily via keyboard;

- Operate "DRY RUNNING" before the actual processing to test the programming settings.

- X. Y. Z axis operate with ball bearings and non-back-lash bearings. With electromagnetic clutch, the machine can optimize the precision of processing. Optical measurement can send feedback to the monitoring system.

Parameters

| Model | CNC430 | CNC540 | CNC850 | CNC1060 | CNC1260 | CNC1470 |

| Work tank(WxDxH) (mm) | 1130*710*450 | 1370*720*450 | 1650*1100*600 | 2000*1300*700 | 2000*1300*700 | 2250*1300*650 |

| Work tablesize (mm) | 700*400 | 850*450 | 1000*600 | 1250*800 | 1250*800 | 1500*900 |

| Work tabletravel (mm) | 400*300*300 | 500*400*300 | 800*500*400 | 1000*600*450 | 1200*600*450 | 1400*700*500 |

| Max. distance from electrode plate to table (mm) | 320~620 | 390~690 | 500~900 | 550~1000 | 550~1000 | 600~1150 |

| Max. electrode weight (kg) | 120 | 150 | 200 | 300 | 300 | 400 |

| Max. workpiece weight (kg) | 1500 | 1800 | 3000 | 3500 | 3500 | 5000 |

| Cross weight (kg) | 1800 | 2500 | 4500 | 5500 | 5500 | 8000 |

| Model | CNC1680 single/double | CNC1880 single/double | CNC2110 single/double | CNC2510 single/double | CNC3010 single/double |

| Work tank(WxDxH) (mm) | 2550*1500*560 | 3000*1500*650 | 3500*1800*650 | 3800*1800*650 | 4500*1800*650 |

| Work table size (mm) | 1700*1000 | 2000*1000 | 2500*1200 | 2700*1200 | 3200*1200 |

| Work table travel (single) (mm) | 1600*800*500 | 1800*800*600 | 2300*900*600 | 2500*900*600 | 3000*900*600 |

| Work table travel (double) (mm) | 1100*800*500 | 1200*800*600 | 1450*900*600 | 1750*900*600 | 2400*900*600 |

| Max. distance from electrode plate to table (mm) | 650~1150 | 600~1200 | 650~1250 | 650~1250 | 700~1300 |

| Max. electrode weight (kg) | 400 | 400 | 450 | 450 | 450 |

| Max. workpiece weight (kg) | 6000 | 6500 | 8000 | 10000 | 15000 |

| Cross weight (kg) | Single 9000 / | Single 13000/ | Single 15000/ | Single 17500/ | Single 23000/ |

| Double 12000 | Double 15000 | Double 17000 | Double 19500 | Double 25000 |

A Japanese DC servo motor optimizes the processing effects of the equipment because of its high stability.

A Japanese DC servo motor optimizes the processing effects of the equipment because of its high stability. Adopting ballscrews made in Taiwan, the CNC EDM machine has high precision and can be controlled easily.

Adopting ballscrews made in Taiwan, the CNC EDM machine has high precision and can be controlled easily. Adopting a linear slide made in Japan, the CNC EDM machine operates with excellent precision.

Adopting a linear slide made in Japan, the CNC EDM machine operates with excellent precision. With the AC servo motor of YASKAWA or Panasonic, the CNC EDM machine has higher processing speed and accuracy.

With the AC servo motor of YASKAWA or Panasonic, the CNC EDM machine has higher processing speed and accuracy. It is easy to learn and understand by adopting interactive editing.

It is easy to learn and understand by adopting interactive editing.

Standard accessories

- 15” LCD monitor

- 1 pcs working lamp & remote control box

- 1 pcs electrode holder & 1 set cartridge paper filters

- Machine level mounts

- Ballscrews & 3-axis linear scales (5μm)

- 1 set tools with toolbox & clamping kits

- Auto fired detect system & extinguisher

- Operation manual & technical data

Optional accessories

- Coolant system & Voltage regulator

- System 3R or EROWA Tool holders

- Magnetic table & EDM oil

- 3-axis linear scales (1μm)

Related products

Send Message

Most Recent

More

Other Products

Videos