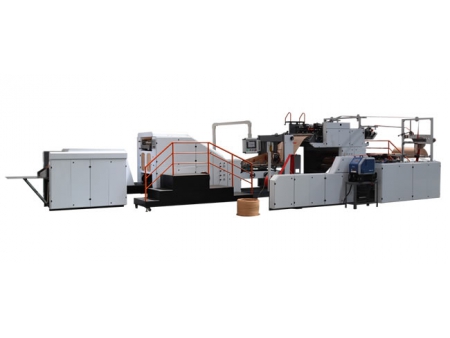

QT6 Automatic Block Making Machine

Description of QT6 Automatic Block Making

This QT6 automatic block making machine has the production capacity of 8640 to 11520 blocks or 120 to 160 cubic meters for one day by 8 working hours. With each mould, it can make 6 blocks in the dimension of 400×200×200mm. Furthermore, various blocks or bricks can be formed by our product because of its changeable moulds.

| Main Technical Specifications | |

| Production per Mould: | 6 pcs/mould (Standard Block: 400x200x200mm) |

| 30 pcs/mould (Solid Block: 240x115x53mm) | |

| 15 pcs/mould (Interlock Paver: 225x112.5x60mm) | |

| 21 pcs/mould (Holland Brick: 200x100x60-80mm) | |

| Cycle Time: | 15-20 seconds |

| Production per Day (8 Working Hours): | Hollow Block (400x200x200mm): 8640-11520 pcs |

| Solid Block (240x115x53mm): 43200-57600 pcs | |

| Interlock Paver (225x112.5x60mm): 17280-21600 pcs | |

| Holland Brick (200x100x60-80mm): 24192–30240 pcs | |

| Vibrating Frequency: | 0-6,000 rpm (rolls per minute) |

| Vibrating Force: | 60 KN |

| Motors Power: | 30 KW |

| Machine Dimensions: | 9680x2800x2800mm |

| Pallet Size: | 850x680mm |

| Gross Weight: | about 7.5T |

| Raw Materials: | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applied Products: | concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields: | widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

| Note: All the production parameters are subject to change without prior notice. | |

Main Features

1. Uses Germany Siemens PLC control system and Siemens Touch Screen.

a.Visualization screen with easy operation;

b.Is able to set up, update and amend the production perimeters, to maximize the production output;

c.Dynamic display of the system's status, automatic trouble shooting and warning notice;

d.Has automatic-locking function, avoiding mechanical accidents caused by operational mistakes;

e.Is able to troubleshoot the machinery via teleservice.

2.Uses high-dynamic proportional and directional valves, which automatically adjust the oil flow and pressure as per specific working requirements, to buffer the hydraulic cylinder when working; uses integrated high-pressure and soft oil pipes, with easy installation;

3. The airbag cylinder is applied to absorb the vibration.

4.Uses multi-shaft rotating and compulsory feeding, which greatly improves the density and intensity of the blocks, and reduces the feeding time as well;

5.Integrated structure of vibrating and moulding platforms, which reduces the weight of the machine, and improves the vibrating efficiency;

6.This product adopts two motors to drive the vibrator through the transmission shaft without inconsistency so as to achieve the purpose of saving power.

7.Uses double-line aero vibration-proof system, which reduces the vibrating force on the mechanical parts, improves the using lifetime of the machine, and reduces the noise;

8.High-precision guide bearings are used to assure the precise movement between the tamper head and the mould;

9.Heavy-duty machine frame, which uses high-intensity steel and advanced heat treatment, is wear resistant.

Five Advantages

1. Frequency Conversional Control Technology

a) This automatic block making machine utilizes the frequency conversion control technology, keeping the precise and parallel movement between tamper head and mould and avoiding its deformation.

b) With the frequency controlled vibration, the product gives proper control on the immediate start and halt of the motors, preventing the motor from overheating caused by long term operation. As the vibration efficiency increases, the production rate will rise correspondently.

c. There is 30% power saved by the product under the frequency conversional control.

2. Double High Dynamic Directional Valves

a) Supporting automatic adjustment on the oil flow and pressure, this valve is used to protect the hydraulic cylinder from being damaged by inertia.

b) It facilitates the stable production performance of the machine.

3. Multi-shaft Rotation at 360° and Compulsory Feeding

a) The automatic block making machine is designed with the feeding device rotating at high speed. The raw material can be blended evenly to make the blocks with optimal density and intensity.

b) With uniform feeding, the product is available in utilizing different raw materials and moulds.

4. German Siemens PLC Control System, Touch Screen and Electrical Components

a) This product is configured with the Siemens PLC control system with high adaptability so as to make sure of its stable and reliable performance.

b) The visualized touch screen is characterized by simple operation.

c) The automatic block making machine introduces the Siemens electrical components.

5. Thermal Treatment on Moulds and Main Parts of the Machine

a) Aside from the heavy duty structure, the product also adopts the durable molds that feature excellent abrasive resistance.

b) The machine is proved with the hardness reaching HRC 52.

c) The service life of the machine is prolonged by 50%.

Production Lines for Block Making

1. Automatic Production Line with Central Control for Block Making

Process: Automatic scaling and batching, automatic mixing, automatic molding or block producing, stacking in pile, transporting by forklift (8 workers needed).

1. Silo

2. Screw conveyor

3. Mixer

4. Aggregate weighing system

5. Color material weighing system

6. Belt conveyor

7. Automatic block making machine

8. Facemix device

9. Piler

10. Central control system

11. Water and cement weighing system

2. Simple Production Line for Block Making

Process: Batching, automatic mixing, automatic molding or block producing, stacking in pile, moving by forklift. (12 workers required)

1. Aggregate weighing system

2. Mixer

3. Belt conveyor

4. Automatic block making machine

5. Control system

6. Piler

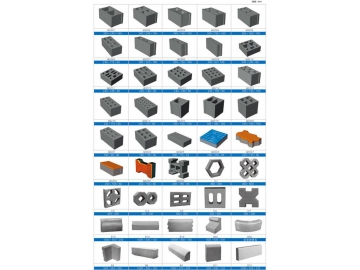

Block and Brick Models