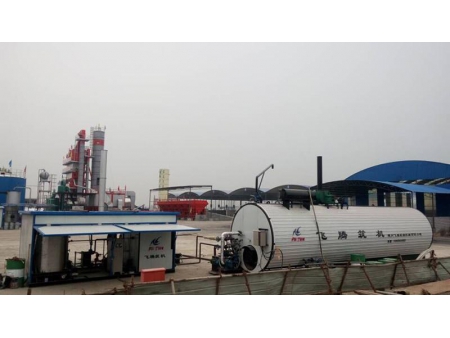

Coal Furnace Air Heating Blower

Request a Quote

Description

The coal furnace air heating blower uses indirect heating technology, which combines combustion and heat exchange, uses anthracite and coke as raw materials, and features high temperature components to act as the heat exchange component. Compared to a one ton boiler, this features a smaller size and a lower price at just half that of a one ton boiler heating system. The fan's air volume can be chosen in a range between 4500 m³/h to 7000 m³/h, and the heating area can reach anywhere between 300 m2 to 1200 m2. The air heating blower is often used for wood drying, medicinal drying, mining, workshop heating, poultry house heating and other fields.

| Model Specifications | Thermal output (kcal/h) | Thermal efficiency (≥%) | Available fuel | Coal consumption (kg/h) | Control Method | Air volume (m3/h) | Hot air heating (℃) | Rated Voltage (V) | Rated Power (kW) | Weight (kg) | Dimension (mm) |

| FSH-10 | 100000 | 85 | blind coal, coke | 6~12 | Auto | 4500 | 60~110 | 380V/220 | 3 | 600 | 1400x1000x2100 |

| FSH-15 | 150000 | 85 | blind coal, coke | 10~18 | Auto | 5000 | 60~110 | 380V/220 | 3 | 750 | 1700x900x2000 |

| FSH-20 | 200000 | 85 | blind coal, coke | 15~25 | Auto | 5500 | 60~110 | 380V/220 | 3 | 850 | 2000x1100x2200 |

| FSH-25 | 250000 | 85 | blind coal, coke | 18~28 | Auto | 7000 | 60~110 | 380V/220 | 3 | 1000 | 2100x1100x2300 |

| FSH-30 | 300000 | 85 | blind coal, coke | 25~35 | Auto | 7000 | 60~110 | 380V/220 | 3 | 1000 | 2100x1100x2300 |

| FSH-10 | 100000 | 85 | blind coal, coke | 6~12 | Auto | 4500 | 60~110 | 380V/220 | 3 | 600 | 1400x1000x2100 |

The heat output power can be customized according to the customer requirements.

Features- The blower features a special three return pattern design, which automatically removes dust inside the exchanger instead of doing so manually.

- Automatic alarm function and automatic protection device;

- Operation can be both started and stopped automatically or manually.

- Automatically control the air intake, the hot air output and the ambient temperature

- The temperature control system can be either a computer controlled or digital display control system.

- The unique overall thermal insulation design minimizes heat loss.

- The specially designed combustion chamber has a long service life and is suitable for all coal quality levels.

- The thermal efficiency is up to 80-95%, which is both efficient and energy-saving.

- The temperature control is easy. After the temperature is set, the blower will automatically start, warm, supply air, and stop. The only manual process is the coal feeding.

- No pollution when heated due to separate channels for smoke and air.

Related products

Send Message

Most Recent

More

Other Products

Videos