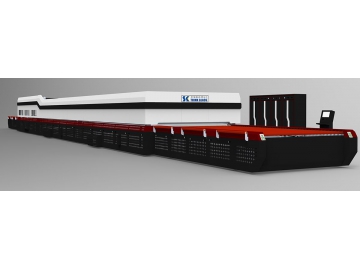

Radiant Heating Flat Glass Tempering Furnace

Designed with a radiation heating system, the radiant heating flat glass tempering furnace is efficient glass processing equipment used for flat glass tempering. Featuring high performance, uniform heating distribution and long-lasting structure, this glass processing machine offers efficient and consistent tempering. It becomes an ideal choice for glass fabricators.

| Model | Max. Glass Size (mm) | Min. Glass Size (mm) | Glass Thickness Range (mm) | Output (batch/hour) | Installed Capacity (kVA) |

| TPG2003 | 2000*300 | 60*60 | 2.85~12 | 18 | 120 |

| TPG2006 | 2000*600 | 80*80 | 2.85~12 | 18 | 250 |

| TPG2010 | 2000*1000 | 120*120 | 2.85~12 | 18 | 250 |

| TPG4010 | 4000*1000 | 120*120 | 2.85~12 | 18 | 315 |

| TPG2012 | 2000*1200 | 160*160 | 2.85~12 | 18 | 315 |

| TPG4012 | 4000*1200 | 160*160 | 2.85~12 | 18 | 400 |

| TPG5015 | 5000*1500 | 200*200 | 2.85~12 | 18 | 500 |

| TPG4220 | 4200*2000 | 240*240 | 4~19 | 18 | 500 |

| TPG5020 | 5000*2000 | 240*240 | 4~19 | 18 | 630 |

| TPG3624 | 3660*2440 | 240*240 | 4~19 | 18 | 500 |

| TPG4224 | 4200*2440 | 240*240 | 4~19 | 18 | 630 |

| TPG5024 | 5000*2440 | 240*240 | 4~19 | 17 | 630 |

| TPG6024 | 6000*2440 | 240*240 | 4~19 | 17 | 800 |

| TPG8024 | 8000*2440 | 240*240 | 4~19 | 17 | 1000 |

- Max. Glass Size (mm): 2000*300

- Min. Glass Size (mm): 60*60

- Glass Thickness Range (mm): 2.85~12

- Output (batch/hour): 18

- Installed Capacity (kVA): 120

- Max. Glass Size (mm): 2000*600

- Min. Glass Size (mm): 80*80

- Glass Thickness Range (mm): 2.85~12

- Output (batch/hour): 18

- Installed Capacity (kVA): 250

- Max. Glass Size (mm): 2000*1000

- Min. Glass Size (mm): 120*120

- Glass Thickness Range (mm): 2.85~12

- Output (batch/hour): 18

- Installed Capacity (kVA): 250

- Max. Glass Size (mm): 4000*1000

- Min. Glass Size (mm): 120*120

- Glass Thickness Range (mm): 2.85~12

- Output (batch/hour): 18

- Installed Capacity (kVA): 315

- Max. Glass Size (mm): 2000*1200

- Min. Glass Size (mm): 160*160

- Glass Thickness Range (mm): 2.85~12

- Output (batch/hour): 18

- Installed Capacity (kVA): 315

- Max. Glass Size (mm): 4000*1200

- Min. Glass Size (mm): 160*160

- Glass Thickness Range (mm): 2.85~12

- Output (batch/hour): 18

- Installed Capacity (kVA): 400

- Max. Glass Size (mm): 5000*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~12

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 4200*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 5000*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 3660*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 4200*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 18

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 5000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 17

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 6000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 17

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 8000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 17

- Installed Capacity (kVA): 1000

Notes: The output is calculated based on the 5mm glass with 80% loading efficiency and 100% finished product rate. The production line configurations depend on the glass thickness.

- The speed for loading and unloading conveyor can be automatically set according to the glass size.

- Feeding length can be set by an automatic device that detects the size of the glass and calculates the cycling time of glass in the heating chamber and cooling zone.

- High speed and perfect glass tempering for any glass factory;

- The glass processing equipment is designed with an intelligent heating control module to ensure precise and stable heating control.

- Fully automated glass tempering for flat glass;

- Uniform heating to tempered glass is achieved using a radiation heating system.

Various glass types can be tempered by the glass tempering furnace, including clear, colored glass, reflective glass. The tempered glass has found wide applications in the glass railings, folding glass systems, glass doors, shower cabins, glass partitions, furniture glasses, refrigerator and stove glasses, solar collector glasses, automotive glasses such as rear and side glasses.

-

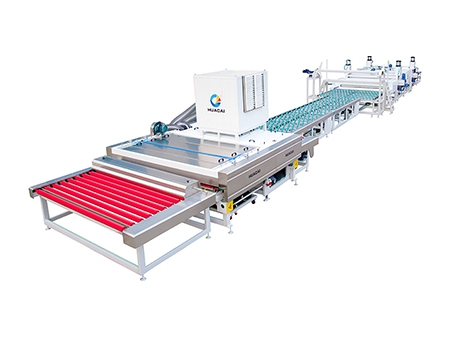

- Conveyor

The conveyor is applicable to loading or unloading the glass to the glass tempering furnace. The conveyor speed can be automatically set according to the glass size. Special design on both sides of the conveyor enables your operator to load or unload of large sized glasses with ease.

-

- Blowing System

Energy savings and reduced energy consumption can be achieved due to the efficient blower and Inverter control.

-

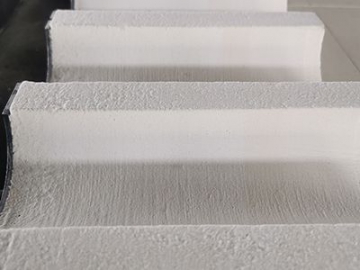

- Well-insulated Furnace Body

The furnace body is equipped with top quality insulation materials to reduce the energy consumption effectively.

-

- Computerized Control System

All processing parameters are allowed to be easily preset and changed throughout the process via the user-friendly human-machine interface. The parameters for glass of various thickness are simply saved as orders. In addition, settings can be saved for future use, including glass type and glass thickness. All these enable easy machine operation.