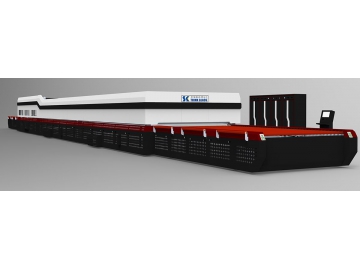

Double-Chamber Glass Tempering Furnace

The glass tempering furnace comes equipped with double heating chambers, offering higher heating efficiency. In order to meet high demanding applications, the working length of heating and quenching can be doubled. The key benefits of this glass processing equipment are reduced heating cycle and increase output, enabling it to be the ideal glass machine for large sized glass factories.

| Model | Max. Glass Size (mm) | Min. Glass Size (mm) | Glass Thickness Range (mm) | Output (batch/hour) | Installed Capacity (kVA) |

| DLTPG2515-2 | 2500*1500 | 200*200 | 2.85~15 | 25 | 500 |

| DLTPG4012-2 | 4000*1250 | 160*160 | 2.85~15 | 25 | 630 |

| DLTPG4015-2 | 4000*1500 | 200*200 | 2.85~15 | 25 | 800 |

| DLTPG5015-2 | 5000*1500 | 200*200 | 2.85~15 | 25 | 800 |

| DLTPG3620-2 | 3660*2000 | 240*240 | 4~19 | 25 | 800 |

| DLTPG4220-2 | 4200*2000 | 240*240 | 4~19 | 25 | 1000 |

| DLTPG3624-2 | 3660*2440 | 240*240 | 4~19 | 25 | 1000 |

| DLTPG4224-2 | 4200*2440 | 240*240 | 4~19 | 25 | 1250 |

| DLTPG5024-2 | 5000*2440 | 240*240 | 4~19 | 25 | 1250 |

| DLTPG6024-2 | 6000*2440 | 240*240 | 4~19 | 24 | 1400 |

| DLTPG5028-2 | 5000*2800 | 300*300 | 5~19 | 25 | 1400 |

| DLTPG6028-2 | 6000*2800 | 300*300 | 5~19 | 24 | 1600 |

| DLTPG5030-2 | 5000*3000 | 300*300 | 5~19 | 25 | 1600 |

| DLTPG6030-2 | 6000*3000 | 300*300 | 5~19 | 24 | 2000 |

- Max. Glass Size (mm): 2500*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 25

- Installed Capacity (kVA): 500

- Max. Glass Size (mm): 4000*1250

- Min. Glass Size (mm): 160*160

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 25

- Installed Capacity (kVA): 630

- Max. Glass Size (mm): 4000*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 25

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 5000*1500

- Min. Glass Size (mm): 200*200

- Glass Thickness Range (mm): 2.85~15

- Output (batch/hour): 25

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 3660*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 25

- Installed Capacity (kVA): 800

- Max. Glass Size (mm): 4200*2000

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 25

- Installed Capacity (kVA): 1000

- Max. Glass Size (mm): 3660*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 25

- Installed Capacity (kVA): 1000

- Max. Glass Size (mm): 4200*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 25

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 5000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 25

- Installed Capacity (kVA): 1250

- Max. Glass Size (mm): 6000*2440

- Min. Glass Size (mm): 240*240

- Glass Thickness Range (mm): 4~19

- Output (batch/hour): 24

- Installed Capacity (kVA): 1400

- Max. Glass Size (mm): 5000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 25

- Installed Capacity (kVA): 1400

- Max. Glass Size (mm): 6000*2800

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 24

- Installed Capacity (kVA): 1600

- Max. Glass Size (mm): 5000*3000

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 25

- Installed Capacity (kVA): 1600

- Max. Glass Size (mm): 6000*3000

- Min. Glass Size (mm): 300*300

- Glass Thickness Range (mm): 5~19

- Output (batch/hour): 24

- Installed Capacity (kVA): 2000

Notes: The output is calculated based on the 5mm glass with 80% loading efficiency and 100% finished product rate. The production line configurations depend on the glass thickness.

- Two times the output and efficiency of a traditional single chamber furnace.

- Suitable for processing coated glass and pattern glass, with minimized glass breakage and higher quality.

- Stable double-chamber design enables easy operation.

- Stable design enables easy operation.

- Tempering and cooling time is precisely controlled, reducing the idling time of the blower. This maximizes energy savings.

- Large sized tempered glass can be made due to a lengthened in-feed and out-feed conveyor.

- The glass tempering furnace is ideal for mass production tempering in architectural or other high-quantity settings.

With double heating chambers, the glass tempering machine is applicable to processing architectural glass, furniture glass, automotive glass, quality low-E glass.

-

- Double Heating Chamber

Double heating chamber reduced heating time, greatly improving heating efficiency.

-

- Quick Installation

-

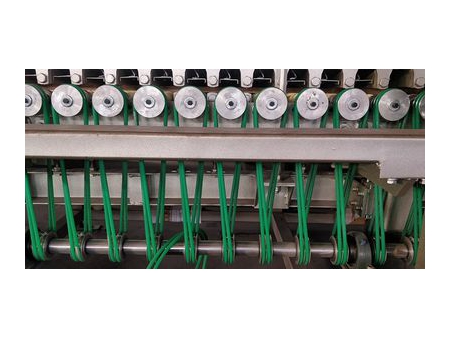

- Quenching Station

Special design for the quenching station minimizes iridescence and produces quality glass.

-

- Lengthened Conveyor

Large-sized Glass Sheet can be tempered due to the lengthened conveyor.