TJ400 Copper Bus Bar & Profile Line

Request a Quote

Continuous Extrusion Machine for Copper Busbar and Profile

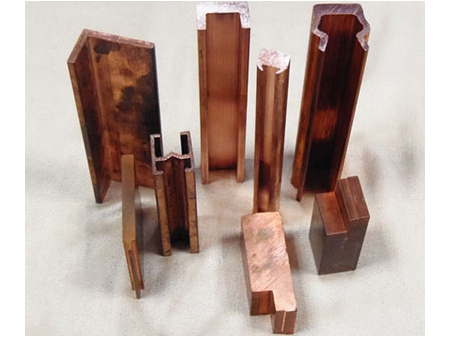

This continuous rotary extrusion line is originally designed for copper busbar production. Also, it can be utilized for manufacturing the copper bar, copper rod, and other types of extruded copper products that are widely used in the motors, transformers, and power distribution cabinets.

Aibang provides complete line of continuous extrusion machines for making copper bar, copper wire, copper strip and copper profiles. Our company is a specialized manufacturer of copper and aluminum extrusion lines. Shown below are details of the copper continuous extrusion line.

Diagram of production line

Technical Specifications

| Model | TJ400 |

| Nominal Diameter of Extrusion Wheel(mm) | Φ400 |

| Power of Main Motor(kW) | 250 |

| Feed Stock Diameter(mm) | Φ20 |

| Copper Bar Max. Width(mm) | 200 |

| Copper Bar Max. Diameter(mm) | Φ80 |

| Sectional Area Range(mm²) | 75-2500 |

| Average Output (kg/h) | 1300 |

Features

- The TJ400 copper busbar continuous rotary extrusion line uses Φ20mm oxygen-free copper rods which can be simply produced using upward casting technique as the feedstock to manufacture high quality oxygen-free copper busbar with a sectional area below 3000mm2.

- Adopting the innovative online scrapless cutting technique, this range of continuous rotary extrusion machine maximizes the feedstock utilization rate, which helps users cut down production cost.

- The modular structure of main components and the extrusion die ensures convenient parts replacement, thus minimizing the maintenance cost.

- The maximum extruded copper product width is up to 170mm, and the average production speed of the continuous rotary extrusion line reaches 1100kg/h.

Copper Wire Production Line, Copper Wire Manufacturing Process, Continuous Rotary Extrusion Equipment Manufacturer