Gypsum Board Dryer

In-feed Section

The in-feed section of the gypsum board dryer is designed to optimize the hydration time, minimize the distance between boards, and allow the wet boards enter into the drying machine in a straight line continuously.

1. Protective guard is installed along the full length of the drive side.

2. The low speed and high speed sections are independently driven, and are connected together via overrunning clutches.

3. The low speed section is driven by the main drive chain. The high speed section is driven by an independent electric motor.

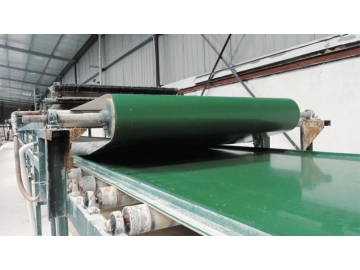

Drying Unit

1. Both the feeding end and output end of the gypsum board dryer come with sealing elements, which prevents entering of external cold air and the loss of the hot air inside the industrial dryer.

2. The dryer rollers are driven by chains, and a periodic lubrication system is available for the chain.

3. Cold air fan is used as the circulating fan usually. According to clients’ demands, hot air fan is available as well.

4. All external ducts and walls are insulated with mineral wool, which ensures heat saving and prevents personnel injury caused by scalding. The surface temperature of the drying equipment is not higher than 20℃.

5. Sliding rail is available under the bottom of the closed section, which avoids damages to the gypsum board dryer caused by thermal expansion.

6. Electrical carbon bearings are installed at both ends of the rollers. The rollers come with surface roughness not higher than 1.6μm, and maximum bouncing less than 0.4mm. Both ends of the roller are precision machined and ground, which extends the service life of the bearings.

7. Mechanisms for air flow direction and air quantity adjustment are available.

8. The position of guide plate is adjustable to prevent over-burning to the edges of gypsum boards.

Output Section

When the gypsum board is delivered from the closed section, the photo eye installed at the output end of the closed section will send out corresponding signals. Then the high speed motor will be started, and the gypsum boards reach the stop gate and wait there. When the stop gate is open, the electromagnetic clutch works to allow the first batch of gypsum board to go out.

The gypsum board dryer is equipped with two electromagnetic clutches. One is for gypsum boards with length between 1.8 and 2.7m, and the other for boards between 3 and 3.6m.

The same as the in-feed section, the low speed and high speed sections are driven independently, and are connected via overrunning clutches. The low speed section is driven by the main drive chain, and the high speed section is driven by an independent electric motor.

Due to high quality graphite sleeves, the gypsum board drying oven support continuous stable operation. The air curtain, side baffle adjustment function, as well as air flow direction and air quantity regulation functions largely reduce the energy consumption and improve the qualification rate of gypsum boards.