Rotary Screw Air Compressor (Low Noise)

Quiet air compressor

Noise from rotary screw air compressors can be overwhelming and annoy those around you. When that happens, it is time to change the squeaky, rattling compressor and replace it with something quieter.

This page details our extremely low noise rotary screw air compressor. As the unit takes up very little floor space, users can easily transport it to a high landing in your manufacturing floor with the use of an elevator. As a popular industrial air compressor, this machine is commonly used for electronics industries, toy industries and mobile phone industries.

The rotary screw air compressor is CE certified, meaning it is in full compliance with EU legislations and can be sold on the European market.

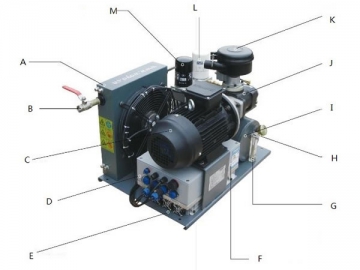

1. Rotary screw mechanism

2. Storage tank for oil and gas

3. Air filter, oil filter, oil and air separator

4. Inlet valve, temperature control valve, minimum pressure valve, safety valve

5. Oil and gas cooling system

Benefits

The Wolkair rotary screw mechanism comes with an independent cooling system. As it is manufactured in one piece, the screw system does not use any pipe fittings. This modular design allows for easy set up and disassembly, which facilitates repair, cleaning and maintenance. Made from fluororubber, the quality O-rings ensure that no leakage occurs at the joint between modules. Both the built in and external oil and air separators are used to control the oil carryover below a 2PPM limit.

IE3 industrial motors have a range of different voltages: 230V, 380V, 420V, 460V, 575 V, and 660V, all at either 50 or 60Hz frequencies.

The operating status of the rotary screw air compressor is closely monitored. Information, including the voltage, current, temperature, and frequencies are clearly displayed. Multiple protection capabilities are also available, including electrical ground and short circuit protection.

A painted inlet valve has been tested to provide 300,000 operation rounds without failing, even under high temperatures and humidity.

WOYO Customer Base

Customers in the USA

1. Sullivan Palatek: Michigan City

2. Dflidacas: Texas

Customers inGermany

1. GASCOT GMBH

2. Walker Druckluft-Technik GMBH

3. Silo Air GMBH

Technical Specifications of Rotary Screw Air Compressor

| Model | HP | Sound | SCFM @ 145 PSI | SCFM @ 116PSI | Length | Width | Height | Weight (kg) | Exit |

| ME7.5 | 7.5 | 63 | 26.13 | 28.96 | 630 | 630 | 1150 | 3/4" | |

| ME10 | 10 | 64 | 33.9 | 38.1 | 630 | 630 | 1150 | 3/4" |

**Note The above model is for reference only. We can customize compressors based on your specific requirements.

Functions/Protections

| Remote control/On-site control | √ |

| RS-485 communication, supporting MODBUSRTU protocol | √ |

| Linkage mechanism/Computer-based centralized control | √ |

| Oil filter (time set-point entry) | √ |

| Air filter (time set-point entry) | √ |

| Oil and air separator (time set-point entry) | √ |

| Lubricating oil(time set-point entry) | √ |

| Lubricating grease (time set-point entry) | √ |

| Belt (time set-point entry) | √ |

| Motor protection (overload, phase loss, imbalance, over-voltage, under-voltage) | √ |

| Blower overload protection | √ |

| Low temperature protection | √ |

| Discharged air over-temperature protection | √ |

| Screw reverse rotation protection | √ |

| Air supply over-pressure protection | √ |

| Sensor failure protection | √ |

VI. Display, Alarm, Interlock (power failure protection)

| Items | Displays | Alarm | Interlock | Note |

| Oil filter (time set-point entry) | √ | √HA | ||

| Air filter (time set-point entry) | √ | √HA | ||

| Oil and air separator (time set-point entry) | √ | √HA | ||

| Phase order protection | √ | √ | √ | |

| Discharge end temperature | √ | √HA | √ | |

| Discharge end pressure | √ | |||

| Thermocouple failure | √ | √ | √ | |

| Startup Timeout | √ | √ | √ | |

| Fan failure | √ | √ | ||

| Main unit failure | √ | √ | √ | |

| Air supply temperature | √ | |||

| Alarm Record | √ | |||

| Operating Time | √ | |||

| Integrated Control | √ |