Rotary Screw Air Compressor (Tank Mounted Compressor)

If you open a factory in a residential area, you want to prevent complaints from the neighborhood about noise. For a reliable and quiet performance in limited spaces, the rotary screw air compressor is an ideal compressed air solution for your industrial process. With a low noise level at 65dB, this industrial air compressor operates quietly.

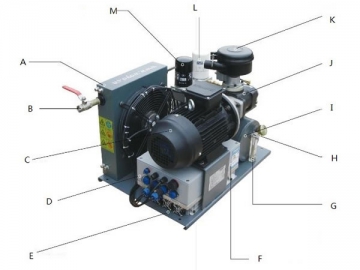

A quick look at the GS series rotary screw air compressor makes it simple, rectangular housing on top of a tank obvious. A closer inspection reveals that it is a small-scale air compressor station. Consisting of a freeze dryer, two-stage filter, precision rotary screw and the storage tank, the tank mounted compressor provides a constant air supply that is clean and free of dust, oil and water.

Its simple belt driven design ensures air compression efficiency and effective cost control. The compact structure, stability, long service life, and limited repair and maintenance needs ensures customers get the best value for their money. The GS series rotary screw air compressor is also suitable for low noise industrial applications.

Technical Specifications of GS Series Rotary Screw Air Compressor

| Model Code | Operating Pressure (bar) | Volumetric Flow Rate (m3/min) | Motor Power (kw/Hp) | Noise dB(A) | Stank Capacity (L) | Dimensions (mm) | Pipe Outlet Diameter G/ Weight (kg) |

| 7~10 | 0.8/0.7/0.6 | 5.5/7.5 | 65 | 270 | 1450*600*1530 | 3/4" 490 | |

| 7~10 | 1.1/1/0.8 | 7.5/10 | 65 | 270 | 1450*600*1530 | 3/4"500 | |

| 7~10 | 1.6/1.5/1.4 | 11/15 | 65 | 270 | 1450*600*1530 | 3/4" 540 | |

| 7~10 | 2.5/2.3/2 | 15/20 | 68 | 500 | 1560*900*1600 | 1" 700 | |

| 7~10 | 3/2.9/2.7 | 18.5/25 | 68 | 500 | 1560*900*1600 | 1" 810 | |

| 7~10 | 3.6/3.5/3.2 | 22/30 | 68 | 500 | 1560*900*1600 | 1" 830 |

**Note: The above mentioned models are for reference only, and we can provide customized models based on customer specifications.

Functions/Protections

| Remote control/On-site control | √ |

| RS-485 communication, supporting MODBUSRTU protocol | √ |

| Linkage mechanism/Computer-based centralized control | √ |

| Oil filter (time set-point entry) | √ |

| Air filter (time set-point entry) | √ |

| Oil and air separator (time set-point entry) | √ |

| Lubricating oil(time set-point entry) | √ |

| Lubricating grease (time set-point entry) | √ |

| Belt (time set-point entry) | √ |

| Motor protection (overload, phase loss, imbalance, over-voltage, under-voltage) | √ |

| Blower overload protection | √ |

| Low temperature protection | √ |

| Discharged air over-temperature protection | √ |

| Screw reverse rotation protection | √ |

| Air supply over-pressure protection | √ |

| Sensor failure protection | √ |

Display, Alarm, Interlock (power failure protection)

| Items | Displays | Alarms | Interlock | Note |

| Oil filter (time set-point entry) | √ | √HA | ||

| Air filter (time set-point entry) | √ | √HA | ||

| Oil and air separator (time set-point entry) | √ | √HA | ||

| Phase order protection | √ | √ | √ | |

| Discharge end temperature | √ | √HA | √ | |

| Discharge end pressure | √ | |||

| Thermocouple failure | √ | √ | √ | |

| Startup Timeout | √ | √ | √ | |

| Fan failure | √ | √ | ||

| Main unit failure | √ | √ | √ | |

| Air supply temperature | √ | |||

| Alarm Record | √ | |||

| Operating Time | √ | |||

| Integrated Control | √ |