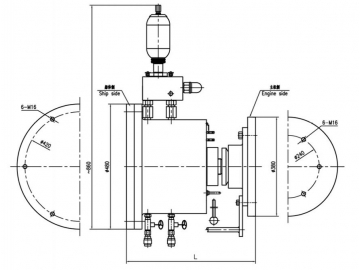

Pneumatic Hydraulic Top Bracing Device

Request a Quote

Application

Pneumatic hydraulic top bracing devices are primarily used in MAN, B&W, and WARTSILA marine power plants. The configuration of the top bracing device depends on the models or requirements of the diesel engine.

Parameters

| Model | Diameter of top bracing hydraulic cylinder | Axial Max. load for single cylinder | Axial Min. load for single cylinder | Installing length and tolerance of hydraulic cylinder (L) | Working stroke | Air supply pressure of compressed air | Pressure setting of high pressure overflow valve | Hydraulic oil | |

| QYDZ300 | 300mm | 127kN | 28kN | 475± 5mm | ±15mm | 0.5-1.0 MPa | 1.7±0.05 MPa | N32 or SAE10-30 | |

| QYDZ300A | 300mm | 183.8kN | 85kN | 585±5mm | ±15mm | 2.5-3.0 MPa | 2.6±0.05 MPa | N32 or SAE10-30 |

Features

- The pneumatic hydraulic top bracing system consists of a top bracing hydraulic cylinder, hand pump station and optional control panel.

- Pneumatic hydraulic top bracing systems are installed between the engine and the hull of a ship in order to reduce vibration frequency caused by the engine.

- The top bracing system is flexible and can easily handle the longitudinal and lateral displacement that results from temperature and loading changes, making it safer and more reliable than a rigid support structure (friction plate).

- The top bracing system consists of two or four top bracing cylinders depending on customer requirements.

Installation

Standalone hydraulic top bracing system is installed on the starboard side of the engine (exhaust side), but portside installation (camshaft side) is available if needed. Installation is only necessary on one side.

Index

marine engine bracing unit, marine parts