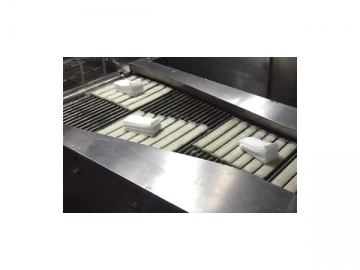

Automatic Wet Wipe Production Line with Stacking Station(Wet wipe cutting, folding, stacking, packing and sealing line)

This wet wipe production line will automatically complete a series of processes for mini wipes with multiple wipes in one bag. The automatic wet wipe production line with a stacking station carries out cutting, single-piece folding, stacking, bag producing, bag-in, liquid filling, and bag sealing of nonwoven fabric.

Rated Speed: 800 pieces/min

Stable Speed: 650 pieces/min

Packing: 5~15 pieces/bag

| Packing Speed | Rated Speed | 800 pieces/min |

| Stable Speed | 650 pieces/min | |

| Packing Dimension | 5~15 pieces/bag | |

| Folded Single Wipe Dimension | 30~50mm | |

| Wipe Cutting Length | 140~1800mm | |

| Packing Film | Composite film | |

| Single Piece Thickness | 40~70µm | |

| Packing Method | Rolling film tapes | |

| Production Material | Dust-free paper, spunlace non-woven fabric | |

- No breakage or weak sealing, all bags are well shaped and neatly stacked.

- Single piece folded, folding deviation ≤3mm.

- Fluent transverse cutting, high cut edge smoothness, cut length tolerance: ± 3mm.

- It can implement the production process with accurate stack counting according to the assigned number. Misplaced tolerance ≤3mm.

- The full servo driving ensured a highly accurate package and stability.

- Wet wipe packaging machine can automatically add material without stop or slowing down.

- Automatically chip and stacking according to the specifications set by the user, automatically eliminating waste.

- Adapting full closed loop lotion accurate humidification, avoid liquid circulation pollution, ensuring the safety and reliability of product quality.

- Patent cutting knife technology triples the service time of the usual knives.

- Stable product quality, reducing liquid waste, cost saving.

- Second-time waste ≤2%, high working efficiency, saving Non-weave fabrics material.

Gachn is a professional multi pack wet wipe packaging machine manufacturer and supplier, leader in designing and manufacturing automated bag packaging equipment. There are wide range of plastic bag packaging machines for packing disposable sanitary and facial tissue products. Gachn is a joint stock company contributed to providing quality multi pack non-woven wet wipe bagging machines and custom packaging solutions for customers.