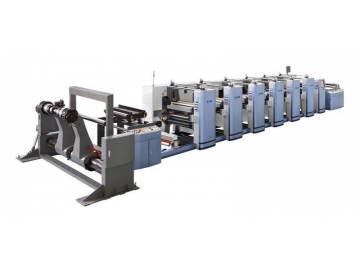

Wide Format Printing Flexographic Press

Request a Quote

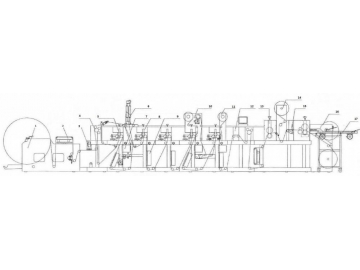

The DG920-1850 flexographic press has a format of printing widest up to 1830mm, and top speed of 150m/min.

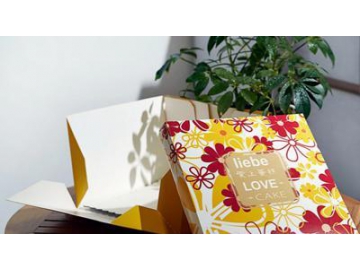

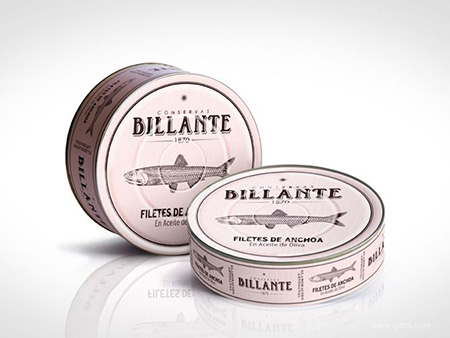

Because the ink used in this press is water-based ink and UV ink, it is especially suitable for eco-friendly package printing, such as the paper box pre-printing carton for food, housing, and wall paper printing.

- unwinder hydraulic station

- paper path deviation correction system

- dedusting system

- speed control unit

- reverse printing unit

- paper path reversible unit

- UV curing system

- printing unit

- infrared drying system

- cool transfer printing unit

- lamination unit

- graphic checking unit

- die-cut unit

- die-cut and waste discharge unit

- longitudinal web cutting unit

- rewinding unit

- rewinder

| Model | 900 | 1000 | 1200 | 1330 | 1430 | 1630 | 1830 |

| Max web width | 920mm | 1020mm | 1220mm | 1350mm | 1450mm | 1650mm | 1850mm |

| Max printing width | 900mm | 1000mm | 1200mm | 1330mm | 1430mm | 1630mm | 1830mm |

| Max die cutting width | 900mm | 1000mm | 1200mm | 1330mm | 1430mm | 1630mm | 1830mm |

| Printing cylinder circumstance | 286-1200mm | 286-1200mm | 286-1200mm | 600-1600mm | 600-1600mm | 600-1600mm | 600-1600mm |

| Dice cutting circumstance | 286-1200mm | 286-1200mm | 286-1200mm | 600-1600mm | 600-1600mm | 600-1600mm | 600-1600mm |

| Max unwind diameter | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm |

| Max rewind diameter | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm |

| Max printing speed | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min |

| Main motor power | 15-22KW | 15-22KW | 15-22KW | 22-30KW | 22-30KW | 22-30KW | 22-30KW |

*Drying method:Hot air, IR or UV

*Oil used:Water base ink, UV ink

*Paper used:17g copy paper, cotton paper, 80-450g chrome paper, aluminum foil paper, bopp, pet, paper board, craft paper

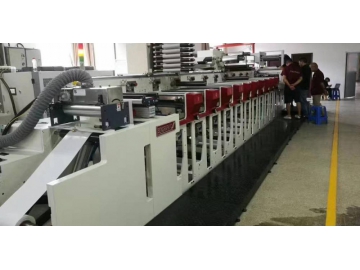

- This machine is able to dedust inside, print and cut.

- Metal anilox roller can do long-time operation and provide ink appropriately.

- Warm drying, IR drying, UV drying are available.

- Closed loop tension control is used to make printing tension much more stable, and register much more accurately.

- Automatically electronic web-guide system.

- Online printing register detection.

- Register system can be operated automatically or manually

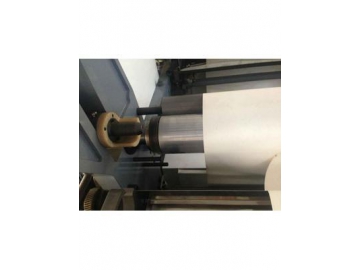

rewind part

rewind part  shaftless printing cylinder

shaftless printing cylinder  unwinder hydraulic station

unwinder hydraulic station  Corona

Corona  camera

camera  color register unit and photosensor

color register unit and photosensor  EPC system

EPC system  PLC touch screen system

PLC touch screen system  gear box

gear box  ink tank

ink tank  lubrication unit

lubrication unit - electrostatic eliminator

Related products

Send Message

Most Recent

More

Other Products

Videos