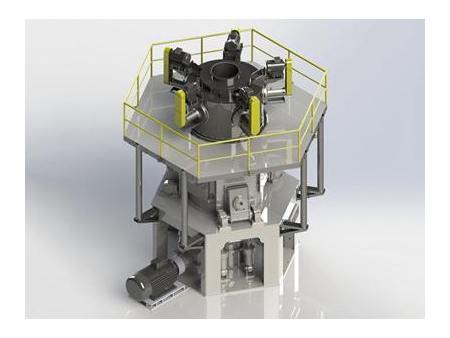

European type High Pressure Ultrafine Grinding Mill

Request a Quote

Application

The micro powder grinding mill is a newly developed device used for the processing of micro powders. It is mainly used to grind non-flammable and non-explosive mineral materials with Mohs hardness under 6 grade and moisture under 5% into powder and the finest particle size of final products can reach up to 2500 mesh. It is quickly becoming the most popular choice to grind non-metallic mineral into micro powders.

Applicable materials

Calcite, chalk, limestone, kaolin, bentonite, talcum, mica, magnesite, illite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rock phosphate, potassium ore, pumice, etc.

| Type | Average running diameter (mm) | Quantity of grinder roll | Feed size (mm) | Finished product fineness (mesh) | Out put (t/h) | Motor power(KW) | Overall Dimension length×wide×height(m) | |||||

| micrometer | mesh | Machine | powder concen-trator | Fan | Feeder | discharge valve | ||||||

| HGM80 | 780 | 21 | ≤10 | 5-44 | 325-2500 | 0.5-4 | 8P-75 | 22 | 2P-45 | 0.06 | 0.75 | 18×3.3×6.4 |

| HGM100 | 990 | 24-32 | ≤10 | 5-44 | 325-2500 | 0.8-6 | 8P-132 | 37 | 2P-75 | 0.06 | 1.1 | 20×3.3×6.8 |

- Large output: micro powder grinding mill can create the powder more evenly under stress by many grinding processes such as impact, rolling, milling and so on. In non-metallic mineral processing industry, the production efficiency of the micro powder grinding mill is double that of double Raymond mills, jet mills and impact mills.

- High precision: flow structure increases the device’s classification precision and the finest final product can be D97≤5um (2500 mesh). Wide adjustment range of fineness: 325mesh-2500mesh. The micro powder grinding mill can not only be used to produce superfine products but also powders typically produced by Raymond mills.

- Stable running: the main engine decreases the shake of device efficiently with the vibration reduction design.

- Easy installation: the complete set is easy to install and has economic space occupation, which is helpful to reduce investment and time of installation. The micro powder grinding mill can run normally and continuously as soon as it is installed.

- Environment friendly: the main engine will be installed underground or in the soundproof room and the fan is equipped with efficient silencer, decreasing the noise efficiently; dust separator uses pulse dust removal technology so that the whole unit will run under negative pressure and there will be few dust pollution at the production field.

Related

grinding plant, industrial grinder, powder milling equipment

grinding plant, industrial grinder, powder milling equipment

Related products

Send Message

Most Recent

More

Other Products

Videos