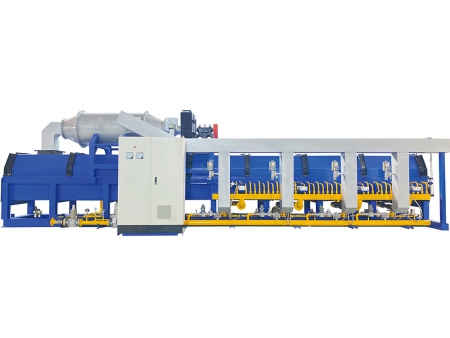

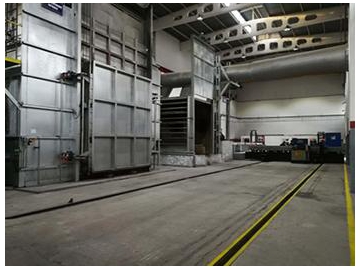

Aluminum Homogenizing Furnace

Process description:

Homogenizing furnace is typically used for heat treatment of aluminum billet after casting process, it aims at eliminating residual stress produced during casting and improving metallurgical results. It is a crucial unit for enhancing the quality of aluminum profiles.

After being homogenized, internal elements of aluminum billet (e.g. Mg2Si and Fe) are consistent. The homogenizing process features less mold consumption and improved surface quality of billet.

A full set of homogenizing furnace consists of homogenization chamber, changing machine (transfer car) and cooling chamber. In the homogenizing furnace, aluminum billet will be heated up to 570℃(±5℃) or process required temperature, then cooled rapidly within a short period, ensuring efficient homogenizing for aluminum billets.

Technical parameters:

| No. | Model | Total load | Cycle mode | Heating areas | Productivity | Energy consumption | Fan power |

| 1 | 10T | Set tonnage ±5% | Vertical circulation | 2 areas | 4-6h per furnace (or by process) | ≦30m³/T.Al | 15-22kw/set |

| 2 | 15-20T | Set tonnage ±5% | Left and right lateral circulation | 3 areas | 4-6h per furnace (or by process) | ≦25m³/T.Al | 22-30kw/set |

| 3 | 25-30T | Set tonnage ±5% | Left and right lateral circulation | 3 areas | 6-8h per furnace (or by process) | ≦25m³/T.Al | 27-45kw/set |

| 4 | 35-60T | Set tonnage ±5% | Left and right lateral circulation | 3 areas | 6-10h per furnace (or by process) | ≦25m³/T.Al | 55-75kw/set |