Packaging Materials

Packaging materials are available in just about any design imaginable, based on specific customer needs across an array of industries. A few of the more common types include cardboard, corrugated packaging, kraft paper packaging, laminated paper packaging and non-woven packaging, each of which, due to their unique structure, offers a lightweight, strong and versatile packaging material solution.

Shown below are some basic factors to consider about packaging solutions to help decide which will best meet your needs.

The experts here at GaoWei are ready and willing to assist customers in selecting the right packaging materials for their needs. Backed by extensive experience working with different packaging options, we know all the ins and outs of each type and can tell you which options will be the best solution for your shipping needs.

- Type 1: Cardboard Packaging

Cardboard, sometimes known as paperboard, is more versatile than most people realize. It comes in a variety of forms and plays a critical role in keeping our lives neat and organized, helps keep food fresh, and keeps other products safe. Because it is both lightweight and durable, and production costs are minimal, it drastically reduces shipping costs. Cardboard boxes are easy to put together, take apart, and seal. In addition, company logos, appealing graphics, product information and other items are easily printed on the packaging. A well-designed cardboard packaging solution not only protects your products, but also separates individual brands from the rest of the pack, helping them stand out to potential customers.

When it comes to choice, value, and quality of cardboard shipping boxes, we here at GaoWei offer unparalleled solutions. We offer cardboard packaging boxes in hundreds of different sizes and have them stored in our warehouse so that they are ready for immediate shipping when needed, ensuring customers need not look any further when choosing the right box size for their needs. Users can also buy corrugated boxes from us in small or large quantities, and as a cardboard box manufacturer, customers often buy directly from us to save both time and money.

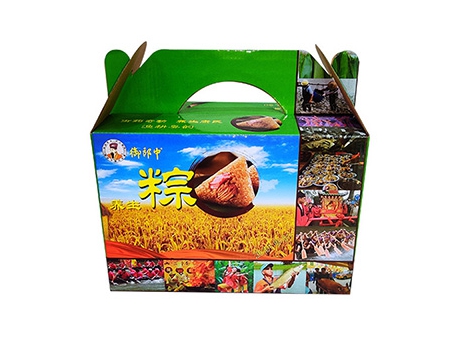

- Type 2: Corrugated Packaging

Corrugated cardboard is the packing material of choice for many industries as its special design ensures it is capable of carrying a wide weight range, protects items against moisture and other elements and offers a sustainable packaging solution. Corrugated board is made from a combination of two sheets of paper, referred to as liners, which are glued to a corrugated inner medium called fluting. These three layers are assembled in such a way that the overall structure is improved and is better than that of each separate layer.

This ingenious construction forms a series of connected arches that are known for their ability to bear a large weight, giving the corrugated board an excellent rigidity and resistance. The air circulation within the flutes also serves as an insulator to protect against temperature fluctuations. Corrugated packaging is available in a variety of different types, each with different flute sizes and profiles, offering the right combination for unique packaging characteristics and performances. Corrugated boards are also cut and folded into an infinite variety of shapes and sizes to be considered corrugated packaging, and it is a high-performance packaging material that is exceptionally reliable for packing, protecting, and promoting an infinite array of products.

Corrugated packaging is also exceptionally customizable. Users can change the board type, the adhesive used, and even the flute size. It can also be coated in a variety of different protective layers. For example, corrugated packaging can be coated in a flame-retardant layer for use when shipping flammable materials, or a moisture resistant layer for shipping in high humidity or wide temperature fluctuation environments. These boxes will protect products inside, even when they are dropped, and easily withstand exposure to high levels of vibration.

Finally, this type of material is also exceptionally cost effective. It is one of the least expensive packaging options, making it an excellent choice for those trying to reduce expenditures on packaging materials without sacrificing product protection.

- Type 3: Kraft Paper Packaging

Kraft paper is a packaging material earning its name from the kraft pulping process. This paper features an excellent tear resistance and high degree of stiffness, ensuring that not only does it have an exceptional strength, but it is 100% environmentally friendly and ideal for an extensive array of packaging uses. Kraft paper offers a raise, bumpy finish that absorbs impact, ensuring the kraft paper will retain its shape, even after impact during shipping.

- Type 4: Laminated Paper Packaging

Laminated paper packaging is a coated or laminated composite material made of paper or paperboard with a plastic layer or surface treatment. It is most widely used in the food and drink packaging industry, as the plastic is used to improve different functions, such as water resistance, tear strength, abrasion resistance and ability to be heat sealed.

Some papers are laminated using heat or adhesive to a plastic film to provide barrier properties during use. Printed papers commonly have a top protective layer to seal prints, provide a wear resistance, and offer a glossy surface if needed. Some coatings are even processed using a UV curing for added stability.

- Type 5: Non-woven Packaging

Non-woven packaging is a popular choice for items such as retail shopping bags, as it feels like canvas but is a type of plastic. It is a clean, recyclable, and machine washable material that is easily customized for your brand and brand messaging. Due to its excellent stiffness, it easily stands on its own for a convenient loading and unloading. Designed to be reused, it is strong, flexible, and non-toxic.