Rapid Prototype

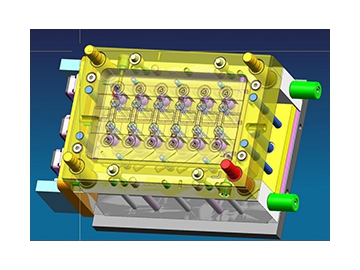

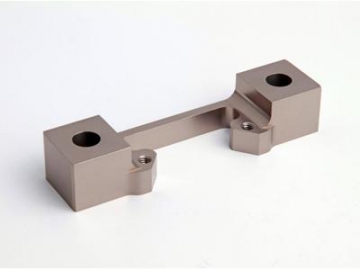

Typically, it takes an initial molding process to produce components. However, producing molds just for a few test parts or non-mass production isn’t the most cost effective choice. Rapid prototyping is a much more economical solution. Hongyu provides rapid prototype service by CNC manufacturing. According to different needs, 3-axis machining, 4-axis machining, 5-axis machining and so on are available to process parts with complex shapes rapidly. Send us samples or blueprints/parameters, so that we can bring your designs and concepts into reality, it’s a good way to make it more efficiency to develop and more cost-effective to produce.

What Is a Rapid Prototype?A prototype, as a vital part of designing and production. It is meant to ensure the practicality of the design, decrease the risk of mass production failure and provide reliable samples for test production. Hongyu provides rapid prototype service without molds, which provides samples for decision makers, engineers and designers to check and confirm their ideas and designs. Shapes, appearances, colors, materials, quality and accuracy of the products are ready for checking and confirming with the prototypes.

By checking prototypes, developers could solve problems of the products developed that might occur before using molds, which would decrease the risk of developing and producing errors, make it more cost-effective for developing and producing.

Hongyu provides CNC rapid processing service and various types of metal materials including aluminum, copper, stainless steels are available for processing, plastics as well.

Materials Available for Processing Aluminum Alloy

Aluminum Alloy 2024 Aluminum, 5052 Aluminum, 6061 Aluminum, 6063 Aluminum, 7075 Aluminum

Copper Alloy

Copper Alloy 101 Copper, 110 Copper, 360 Brass, 464 Brass, 936 Bronze

Stainless Steel

Stainless Steel SUS303 Stainless Steel, SUS304 Stainless Steel, SUSU316 Stainless Steel, SUS420 Stainless Steel, SUS440c Stainless Steel

Steel

Steel 1018 Steel, 1040Steel, 1045Steel, 12L14Steel, 4130Steel, 4140Steel

Plastics

Plastics ABS,POM,Acetal.PMMA,HDPE,Nylon, PEEK, PTFE,PC,PA,BT,PVC, Silicon rubber

- Check the appearance design, bring designer’s idea into reality, and find out disadvantages in order to fix them before mass production.

- Check the structure and functional design, check its rationality and practicability and difficulty in production, to find out shortages and errors of the structure and function, and optimize it.

- Decrease the risk of failure of using mold directly, to avoid loss and save cost.

- Use prototypes to pre-advertise (for example, attending exhibitions) before the molds are ready, and prepare for production in advance.

As a rapid prototype service provider, we have 15 years of experience, and are equipped with complete CNC processing equipment operated by experienced workers, to ensure the cost-effective service for you.