Steam Turbine (Turbine with Organic Rankine Cycle System)

The steam turbine uses organic compound instead of water as the working medium. It can recycle the low temperature heat (70~300℃), such as waster hot water, exhaust gas, solar power, and geothermal energy, for the organic Rankine cycle (ORC). Currently, this kind of ORC steam turbine has been used for various industries like steel, cement, chemical, ceramic, glass, non-ferrous metal, and so on.

Features of the Steam Turbine

1. The ORC turbine can take advantage of various kind of heat from 70℃ to 300℃ by different methods.

2. No vacuum equipment is needed, but the system has to be operated with back pressure.

3. The installation for the back pressure steam turbine is quite simple. The other features include reasonable structure, stable working performance and high energy efficiency.

4. We can provide suitable equipment according to the heat source you have.

Technical Parameters of the Steam Turbine

| Model | Capacity(MW) | Inlet Pressure (MPa) | Inlet Temperature(℃) | Exhaust Pressure (MPa) |

| 0.26 | 0.976 | 115 | 0.154 | |

| 0.5 | 0.976 | 115 | 0.154 | |

| 1 | 3.6 | 160 | 0.25 | |

| 2 | 3.6 | 160 | 0.25 | |

| 3 | 3.3 | 205 | 0.116 |

Note: For more parameters, please contact us. Custom steam turbines are also available according to your requirements.

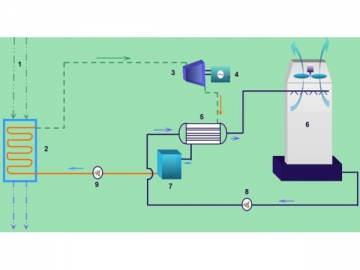

Organic Rankine Cycle (ORC) cogeneration technology

Schematic diagram for Organic Rankine Cycle (ORC) cogeneration system with low temperature exhaust heat

1. Low temperature exhaust heat

2. Heat recovery boiler with organic working medium

3. ORC turbine

4. Generator

5. Condenser

6. Cooling tower

7. Liquid container

8. Circulating pump

9. Working medium pump