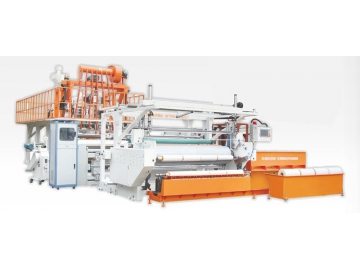

XHD-80/120/80*2350 Fully Automatic Extrusion Stretch Film Line

This product has been discontinued and removed from our shelves.

Fully automatic extrusion stretch film line is a cast stretch film production machine group features high plasticization, easy operation, long life and energy-saving. The film is modified and designed based on the years’ experience on the cast equipment manufacturing and the production experience from the customers, combined with the advanced technology from oversea.

The machine group is modified and designed based on the years’ experience on the cast equipment manufacturing and the production experience from the customers, combined with the advanced technology from oversea.

The machine group is mainly for the production of LLDPE film, LDPE film, PE film and CPE film, etc.; it adopts advanced intelligent industrial controlling system, with loading system which ensures easy and safe operation, a tighter and more even roll winding.

All the designs ensure the film quality, enhance the production efficiency, lower down production cost and create more value. The installation of swing system on the subsidiary machine can enhance the evenness and appearance of the film rolls which make the products more competitive.

- Fully automatic thickness gauge (Chinese or international brand)

- Fully automatic T-die (Chinese or international brand)

- Fully automatic paper cores loading and unloading system, the real automatic manipulation.

- Vacuum box system

- Melting gear pump and PID controlling system

- Micro-computer & touch screen accurately controlled temperature controller

- Fully automatic robot hand roll change and air shaft loading system

- Automatic screen changer with hydraulic station

| Model | XHD-LΦ 80/120/80x2350 |

| Film thickness | 12-50 microns |

| Screw diameter | 80/120/80mm |

| Production capacity | 250-400 KGS/H |

| Effective screw L/D | 32:1 |

| Film layer structure | ABC/ACBCA |

| Speed of screw | 50-150 RPM |

| Gross weight | 20,000 KGS |

| Finished film width | 2000mm/4x500mm/4x450mm |

| Dimensions | 16500 (L) X6500 (W) X5000 (H) mm |

| Total Power | 300 KW |